Aug . 11, 2025 10:29 Subira kurutonde

Small Square Tin Manufacturing Process

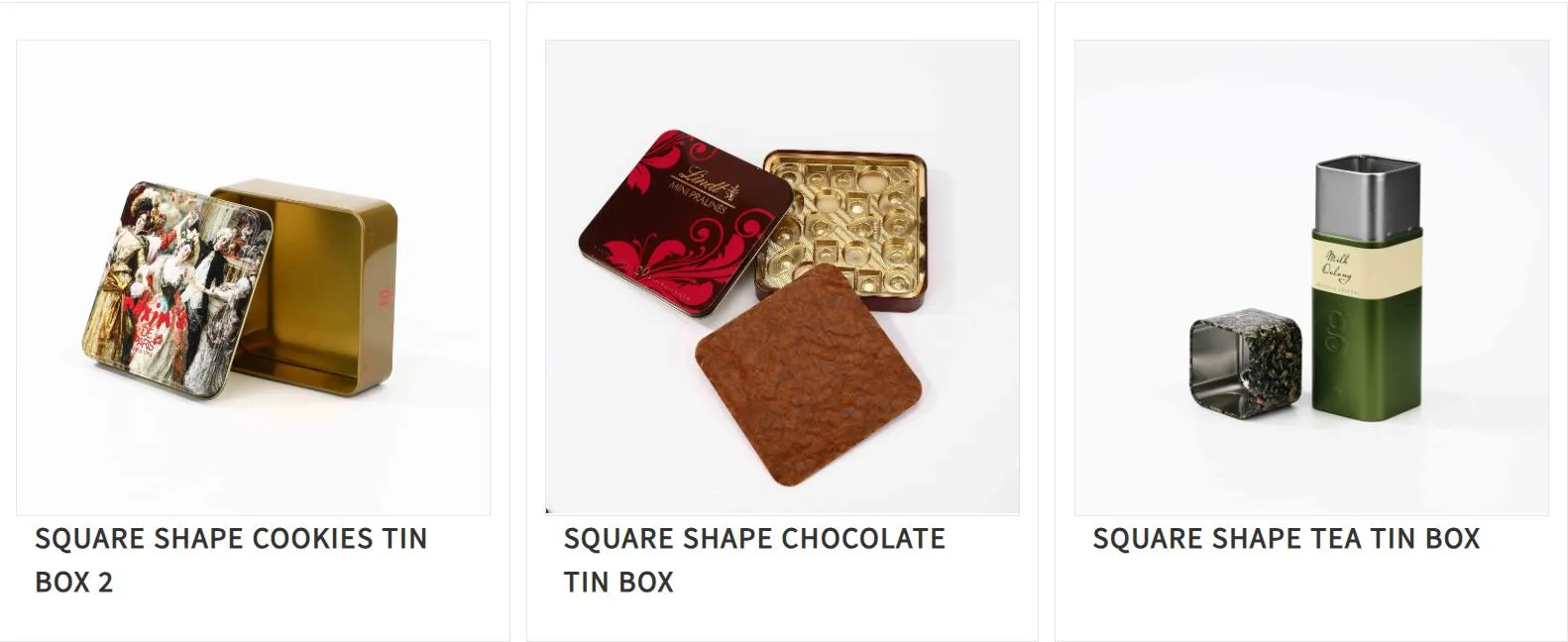

The production of amabati mato containers combines precision engineering with artistic craftsmanship to create functional yet beautiful packaging solutions. From the versatile amabati kare to the charming bombo kare, each product undergoes a meticulous manufacturing journey that ensures quality, durability, and aesthetic appeal.

Small Square Tin Material Preparation

- Tinplate selection- High-quality steel sheets chosen for amabati mato production

• Material coating - Electrolytic treatment applied to amabati kare metal for corrosion resistance

• Sheet cutting - Precision machinery cuts raw materials to bombo kare specifications

• Quality inspection - Each metal sheet checked before amabati mato forming begins

• Protective layering - Food-grade coatings applied for amabati kare interior surfaces

Square Tin Can Forming Process

- Blank stamping- Flat sheets pressed into basic amabati mato shapes

• Body forming - Special dies shape the amabati kare walls and corners

• Edge curling - Smooth rolled edges created on bombo kare openings

• Seam welding - Precision welding joins amabati mato side seams

• Structural testing - Each amabati kare undergoes pressure and stress tests

Candy Square Box Decoration Techniques

- Surface treatment - Cleaning and priming for amabati matoprinting surfaces

• Base coating - Uniform color application on amabati kare exteriors

• Graphic printing - High-resolution designs transferred to bombo kare surfaces

• Special finishes - Embossing, foil stamping or varnish for amabati mato enhancement

• Curing process - Heat treatment sets all amabati kare decorations permanently

Small Square Tin Lid Production

- Separate stamping - Lids formed specifically for each bombo karedesign

• Hinge attachment - For amabati mato versions with stay-on lids

• Sealing mechanisms - Snap-fit or friction-fit amabati kare closures created

• Safety features - Child-resistant options for certain bombo kare applications

• Fit testing - Every amabati mato matched with perfectly fitting lid

Square Tin Can Quality Assurance

- Dimensional checks - Precision measurement of each bombo kare

• Print quality - Color matching and graphic alignment on amabati matoverified

• Function testing - Lid fit and opening ease evaluated for every amabati kare

• Food safety - Candy square box interiors tested for coating integrity

• Final inspection - Comprehensive review before amabati mato packaging

Candy Square Box Packaging

- Protective wrapping - Individual amabati matounits safeguarded

• Bulk packaging - Efficient amabati kare grouping for shipment

• Labeling - Product information marked on bombo kare cartons

• Palletizing - Secure stacking for amabati mato transportation

• Storage - Climate-controlled warehousing for amabati kare inventory

Small Square Tin FAQS

Q: How does the design of a small square tin differ from a square tin can for storage purposes?

A: A amabati mato typically features a lightweight, removable lid and is designed for decorative or small-item storage, such as jewelry or spices. A amabati kare, however, often has a more rugged construction with welded seams and airtight seals, ideal for preserving food items like nuts or coffee. The tin prioritizes aesthetics and accessibility, while the can emphasizes durability and product freshness.

Q: What materials are used in a candy square box versus a functional small square tin?

A: Candy square boxes often combine tinplate with decorative elements like glossy finishes, foil stamping, or window cutouts to showcase sweets. Functional small square tins may use simpler tinplate or aluminum, focusing on practicality over ornate design. Candy boxes might include paper linings to prevent stickiness, while utility tins may have plain interiors for easy cleaning.

Q: Can a square tin can be customized for branding as effectively as a candy square box?

A: Yes, but customization depths vary. Square tin cans can be printed with logos or patterns via screen printing, while candy square boxes allow more intricate designs, such as 3D embossing or vibrant full-color wraps. Candy boxes often incorporate decorative elements like ribbons or magnetic closures for a premium feel, which are less common in industrial tin cans meant for bulk storage.

Q: How do you maintain the finish of a small square tin compared to a cardboard candy square box?

A: Small square tins require minimal upkeep—wipe with a soft cloth to remove dust and avoid harsh chemicals that could damage the paint or lacquer. Cardboard candy square boxes are more delicate; keep them dry to prevent warping and use protective sleeves for long-term storage. Tin’s resistance to moisture and fading makes it suitable for reusability, while cardboard boxes are better for temporary or disposable use.

Q: What occasions are best suited for a candy square box versus a utilitarian small square tin?

A: Candy square boxes shine for gifting occasions like holidays or weddings, where their decorative appeal enhances presentation. They’re ideal for short-term use with chocolates, mints, or gummies. Utilitarian small square tins, with their durable metal construction, are perfect for long-term storage of items like screws, buttons, or craft supplies. The tin’s reusability makes it a sustainable choice for everyday organization.

Welcome to Shijiazhuang Longzhitai Packaging—where packaging is a love letter to your brand! For 10 years, we’ve crafted metal and compound marvels that transform products into unforgettable experiences.

Our 5 automated lines hum with creativity, churning out 3M+ tins monthly—from tinplate heart boxes to wooden tea caskets. With 20 designers shaping dreams, we don’t just make packaging; we engineer stories. Picture a caviar tin embossed with your logo, a pharmaceutical pack that’s child-safe yet chic, or a Christmas tin that doubles as a keepsake.

Eco-warriors, rejoice: our infinitely recyclable metal wonders (hello, tinplate and aluminum!) marry sustainability with style. Hinged lids, 3D embossing, matte finishes—name your magic, we’ll mold it. As a family-run factory, we blend lean manufacturing with artisanal soul. Dive into custom molds, CAD wizardry, and fast turnarounds at www.packaging-help.com . Let’s wrap your vision in metal magic!

-

Small Square Tin Manufacturing Process

AmakuruAug.11,2025

-

Design Ideas for Round Biscuit Tin Box

AmakuruAug.11,2025

-

Design Ideas for Heart Box

AmakuruAug.11,2025

-

Cost Analysis of Rectangle Tin Can

AmakuruAug.11,2025

-

Choosing the Right Round Plastic Buckets

AmakuruAug.11,2025

-

Applications of Pails Buckets

AmakuruAug.11,2025