Jul . 29, 2025 23:40 Back to list

Top Large Metal Box Manufacturers – Custom Size & Durable Quality

In today's evolving industrial landscape, large metal box manufacturers play a crucial role in providing reliable, robust, and customizable containment solutions across sectors such as petrochemicals, waterworks, metallurgy, and electronics. Whether it's for high-volume storage, complex machine enclosures, or specialized packaging like the Square Shape Thin Chocolate Tin Box, choosing the right supplier and understanding the latest trends is fundamental to optimizing operational efficiency, safety, and longevity.

- Core Topics: Industry analysis, latest manufacturing techniques, material technology, product comparison, custom engineering, and real-world application cases.

- Including: large metal box supplier selection guides, large metal box factory process insights, and insights into large metal box service excellence.

1. Industry Trends in Large Metal Box Manufacturers

The global metal enclosure market is experiencing a sharp uptick, projected to reach $9.8 billion by 2028 (Markets&Markets report), propelled by growing investments in smart factories, power distribution systems, and resilient industrial packaging. Technological improvements—such as precision CNC machining, sustainable material sourcing, and adherence to international safety norms (ISO 9001, ANSI)—have propelled large metal box manufacturers to deliver more durable, tailor-fit, and cost-effective solutions.

- Custom Engineering: Demand is shifting to personalized, project-driven box sizes up to 3000mm and with precise tolerance (as tight as ±0.15mm).

- Material Innovation: Rise of 304/316 stainless steel, aluminum 6061-T6, and zinc-galvanized steel, offering corrosion indices >9.5 on 1–10 oxide scale.

- Regulatory Compliance: Mandatory factory certification: ISO9001 (Quality), ISO14001 (Environment), and, for food/medical, FDA-grade metal coatings.

2. Leading Large Metal Box Manufacturers: Parameter Table & Vendor Comparison

Selecting the optimal large metal box supplier involves balancing technical performance, compliance, and innovative service. Below is a comprehensive table comparing core offering parameters of industry-leading large metal box manufacturers:

| Manufacturer Name | Location | Material Options | Max Size (mm) | Certifications | Min Tolerance | Industry Served | Warranty (Yrs) |

|---|---|---|---|---|---|---|---|

| BoxTech Industrial Ltd | China, Europe | SS304, SS316, Alu 6061-T6 Zinc Steel | 3000×2000×2200 | ISO9001, ANSI, CE | ±0.15mm | Petro, Food, Waterworks | 8 |

| Jensen Metalworks | USA | Carbon Steel, Aluminum | 2500×1500×1500 | ISO9001, UL508A | ±0.20mm | Power, Automation | 10 |

| NovaBox Gmbh | Germany | Stainless, Galvanized | 2700×1700×1800 | EN ISO3834, RoHS | ±0.10mm | Energy, Automotive | 7 |

| MetalBoxPro | India, UAE | 316L SS, Mild Steel | 1900×1550×1580 | ISO9001, TUV | ±0.16mm | Chemical, Water | 6 |

Takeaway: Companies like BoxTech Industrial Ltd and Jensen Metalworks combine advanced machining with global certification to address cross-industry challenges while providing extended warranties and rapid prototyping services.

Contact Top Large Metal Box Manufacturer3. Manufacturing Process of Large Metal Box Manufacturers

Industry-leading large metal box manufacturers, including those behind the Square Shape Thin Chocolate Tin Box, employ a rigorous, multi-stage process that ensures superior mechanical integrity, surface finish, and longevity.

- Key Control Points: 100% visual inspection post-coating; batch-level tensile and corrosion test in line with ISO9227; full traceability by barcode system.

- Service Lifetime: Typical lifecycle reaches 7–15 years with optimal installation and maintenance.

- Standards Compliance: All units validated per ANSI/EIA-310 (mounts & sizes), with welding joints conforming to EN ISO 3834-2 for high-integrity applications.

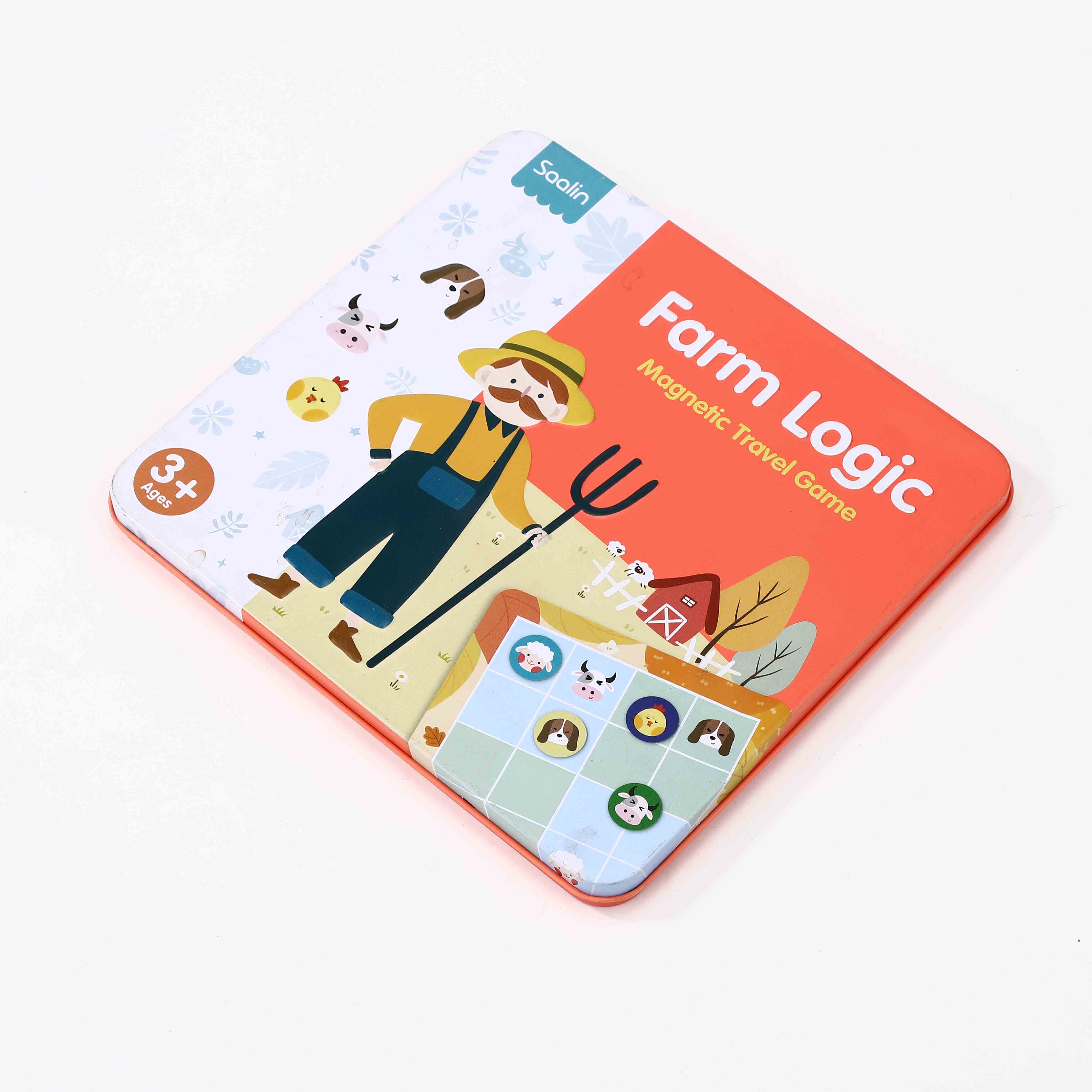

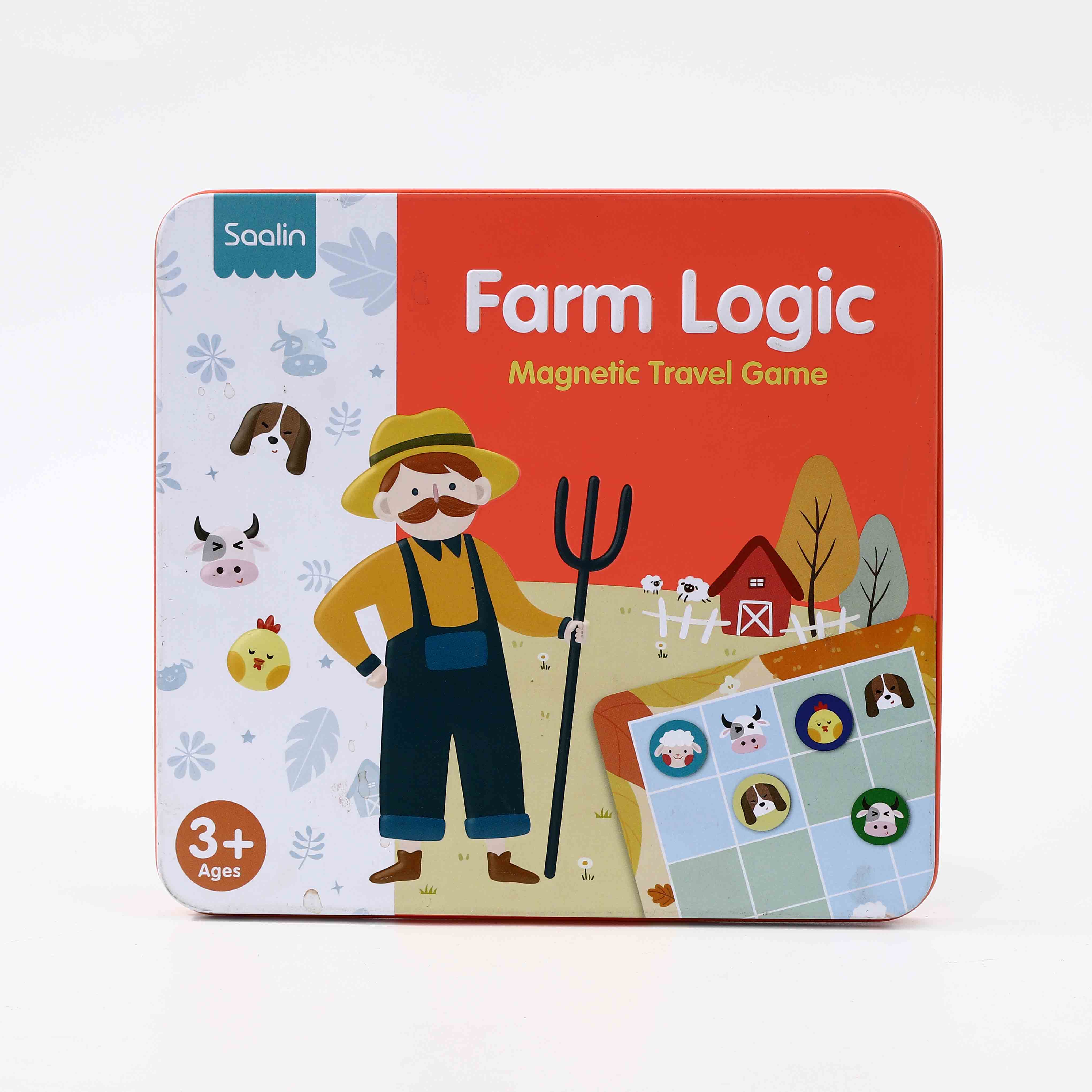

4. Product Specification & Technical Comparison: Square Shape Thin Chocolate Tin Box

A signature product by large metal box manufacturers, the Square Shape Thin Chocolate Tin Box demonstrates how modular design, material selection, and advanced finishing come together for premium results in food and gifting industries.

| Parameter | Square Thin Chocolate Tin Box | Standard Steel Storage Box | Heavy-duty Industrial Box |

|---|---|---|---|

| Material | Tinplate, food-safe lacquer | Galvanized steel | 304 Stainless steel |

| Dimensions | 122×122×24 mm | 300×150×120 mm | 1000×800×500 mm |

| Thickness | 0.22 mm | 1.2 mm | 2.0 mm |

| Surface Finish | Gloss + multicolor offset print | Powder coated | Satin-polished |

| Certifications | FDA, LFGB, ISO9001 | ISO9001, CE | ANSI, EN ISO 3834 |

| Corrosion Resistance | 200h Salt Spray | 350h Salt Spray | >750h Salt Spray |

| Main Application | Chocolates, Candy Gift | Parts Storage | Industrial Machining |

Summary: For food contact packaging, large metal box manufacturers employ FDA/LFGB-certified coatings and advanced offset printing for superior shelf appeal and corrosion resistance. For industrial applications, priority shifts to extended salt-spray performance, impact durability, and ANSI/ISO-tested weld strength.

5. Custom Solutions by Leading Large Metal Box Manufacturers

- Project-driven Design: Whether in food, water, or heavy industry, reputable large metal box service providers offer 3D CAD modeling, rapid prototyping, and digital proofing for accurate project fit and visual approval.

- Premium Process Control: Large metal box factory environments are equipped with ISO/ANSI-compliant labs, 7–10 step QA checkpoints, and real-time monitoring.

- Surface & Printing: From multi-color offset for retail tins, to powder and epoxy coatings for outdoor/industrial boxes, manufacturers offer photorealistic branding and extreme weather endurance.

- Packaging Safety: Final products are shock-tested and packed in certified export crates, compliant with ISPM 15 international phytosanitary standards.

- Engineering Collaboration: Dedicated technical teams assist with regulatory documentation, FEA structural simulations, and multi-language support.

6. Application Scenarios: Real-World Use Cases & Client Feedback

- Petrochemical Industry: Custom stainless steel boxes shield critical instrumentation at refineries, withstanding saline spray and heat up to 130°C.

- Metallurgy & Mining: Heavy-duty boxes with anti-vibration welds protect relay systems and automation PLCs in open-pit mining.

- Food & Confectionery: Square Shape Thin Chocolate Tin Box for international brands—yielding 0.6% reject rate based on 2023 annual audit, well below industry average.

- Municipal Infrastructure: Extra-large galvanized enclosures (up to 2.95m) for data and power connections in underground water management.

7. Fulfillment, Warranty Policy, and Client Support

- Order Cycle: Standard off-the-shelf boxes ship in 7 days; custom runs (with tooling) typically delivered in 16–28 days after design approval.

- Warranty: Minimum 5-year functional warranty; up to 10 years for industrial-grade models. Extended warranty & on-site inspection available.

- Post-sale Support: 24/7 technical support, online assembly guides, and spare part logistics to 120+ countries.

- Certification Traceability: Each box comes with batch number, material test certificate, and conformity documents (ISO, FDA, ANSI compliance as relevant).

- Return & Remake: Defect rate below 1% with free remake or return support for non-conforming items.

8. Professional FAQ about Large Metal Box Manufacturing

A: Common materials include tinplate, 304/316 stainless steel (excellent corrosion resistance and strength), aluminum alloys (notably 6061-T6 for high mechanical loads), and zinc-galvanized steel. All are often certified under ISO9001 and FDA/LFGB where food use is involved.

A: Precision CNC cutting, monitored with laser measurement (±0.1–0.2 mm), ensures repeatability. Random dimension checks conforming to ANSI/ISO standards are performed at each production stage.

A: Surface finishes may include powder coating, multicolor offset printing, or food-safe epoxy lacquers. All must pass adhesion, salt spray, and lead content tests (per EN71/REACH for food packaging, and ISO9227/ASTM B117 for industrial use).

A: Key certifications—such as ISO9001, FDA, CE, or UL508A—are required by different regions. Compliance guarantees entrance into regulated markets and reduces customer risk.

A: Standard MOQs typically begin at 500 units, but some manufacturers offer pilot runs from 100 units. Digital prototyping and 3D CAD assure full customization with rapid feedback loops.

A: Service lifetimes range between 6 and 15 years, contingent upon alloy, coating, and exposure. Routine inspection and maintenance, as advised in the supplied manual, prolongs box longevity.

A: Leading manufacturers integrate offshore warehousing, multilingual documentation, and direct supply chain partnerships, ensuring prompt fulfillment and technical support worldwide.

9. Conclusion & Industry Resources

Large metal box manufacturers are engineering partners for demanding applications—delivering specification-driven, certified, and robust enclosures from chocolates to chemical plants. Whether you require a sophisticated Square Shape Thin Chocolate Tin Box for gourmet gifting or a rugged, anti-corrosive bulk storage unit, choosing the right supplier is critical to your operation’s safety and success.

- Want more? See in-depth peer reviews and technical discussions:

-

Premium Large Metal Box Manufacturers for Industrial Solutions

NewsJul.30,2025

-

Top Large Metal Box Manufacturers – Custom Size & Durable Quality

NewsJul.29,2025

-

Large Metal Box Manufacturers – Custom Durable Solutions for All Industries

NewsJul.29,2025

-

Top Large Metal Box Manufacturers & Supplier with Custom Solutions

NewsJul.29,2025

-

Large Metal Box Manufacturers for Custom Industrial Solutions

NewsJul.29,2025

-

Steel Pail with Lid Manufacturers - Durable & Customizable Solutions

NewsJul.28,2025