kol . 11, 2025 10:14 Povratak na popis

Applications of Pails Buckets

From industrial settings to home entertainment, pails buckets serve numerous practical purposes across various industries. The versatile 3 gallon metal bucket and specialized bucket rollers systems demonstrate how these containers have evolved beyond simple storage solutions. This article explores the diverse applications of these essential tools in different environments.

Bucket Rollers for Industrial Use

- Assembly line integration- Bucket rollers enable smooth transportation of 3 gallon metal bucket containers along production lines

• Material handling systems - Engineered bucket rollers facilitate efficient movement of heavy pails buckets in manufacturing facilities

• Packaging operations - Custom bucket rollers support automated filling and sealing processes for 3 gallon metal bucket products

• Warehouse logistics - Conveyor-style bucket rollers optimize storage and retrieval of filled pails buckets

• Ergonomic solutions - Height-adjustable bucket rollers reduce worker strain when handling heavy 3 gallon metal bucket containers

Pails Buckets in Food Service

- Bulk ingredient storage- Commercial kitchens use pails buckets for flour, sugar and other dry goods

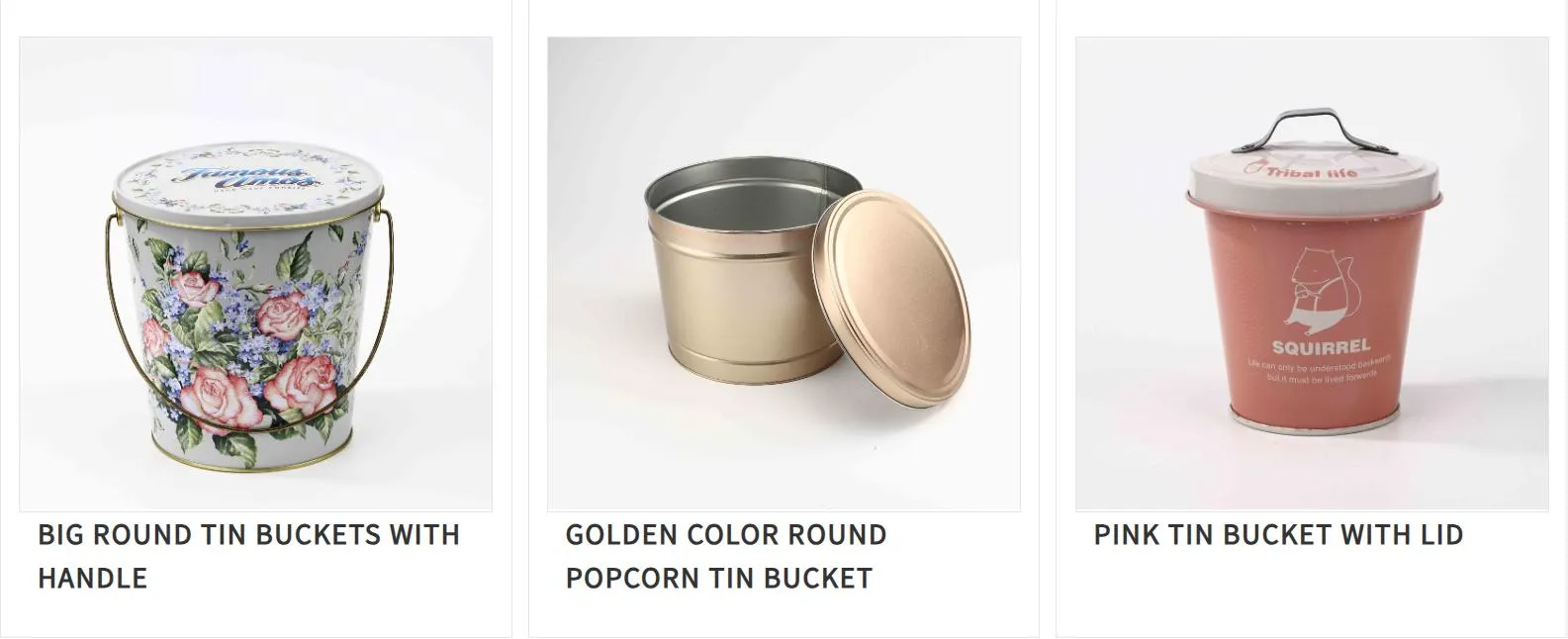

• Popcorn serving containers - Theatres utilize 3 gallon metal bucket for premium snack presentations

• Food transportation - Caterers rely on sealed pails buckets for safe meal delivery

• Buffet stations - Decorative 3 gallon metal bucket serve as elegant ice buckets or condiment holders

• Compost collection - Eco-conscious restaurants implement pails buckets for organic waste management

3 Gallon Metal Bucket for Home Use

- Home organization- Versatile 3 gallon metal bucket stores tools, toys, and household items

• DIY projects - Crafters use pails buckets for paint mixing and supply organization

• Outdoor activities - Durable 3 gallon metal bucket serves as camping gear or beach essentials carrier

• Gardening applications - Homeowners utilize pails buckets for soil transport and plant watering

• Seasonal decorations - Festive 3 gallon metal bucket become holiday centerpieces or treat containers

Bucket Rollers in Agricultural Settings

- Harvest collection- Mobile bucket rollers systems streamline fruit and vegetable gathering

• Feed distribution - Farm operations use pails buckets with bucket rollers for efficient animal feeding

• Milking operations - Dairy farms implement specialized 3 gallon metal bucket with hygienic bucket rollers

• Produce washing - Custom bucket rollers systems facilitate cleaning of harvested crops in pails buckets

• Farm storage - Organized bucket rollers racks maximize space for 3 gallon metal bucket containers

Pails Buckets for Retail Display

- Bulk product merchandising -Stores display goods in attractive pails buckets for rustic appeal

• Promotional packaging - Branded 3 gallon metal bucket serve as premium gift containers

• Seasonal displays - Thematic pails buckets create eye-catching retail arrangements

• Interactive stations - Customer self-serve areas utilize 3 gallon metal bucket with scoops

• Point-of-purchase - Strategically placed pails buckets increase impulse purchases

Bucket Rollers FAQS

Q: How do bucket rollers enhance the functionality of pails buckets in industrial settings?

A: Bucket rollers are mechanical components that enable smooth transportation of pails buckets on conveyor systems, reducing friction and improving handling efficiency. In warehouses or manufacturing lines, they allow automated movement of heavy buckets, minimizing manual labor. For example, rollers with anti-slip surfaces prevent buckets from tipping, while adjustable models accommodate different pail sizes, from small utility buckets to large industrial containers.

Q: What maintenance is required for bucket rollers used with 3 gallon metal buckets?

A: To ensure longevity, bucket rollers should be regularly inspected for wear, especially when handling 3 gallon metal buckets that may carry corrosive materials. Clean rollers of debris and apply lubricant to axles to prevent rust and jamming. For metal buckets, which are heavier than plastic ones, check roller bearings for signs of fatigue—replacing them if there’s excessive play. This maintenance prevents damage to both rollers and buckets, ensuring consistent performance.

Q: Can bucket rollers be customized for specific 3 gallon metal bucket applications?

A: Yes, bucket rollers can be tailored to fit 3 gallon metal bucket needs. For instance, stainless steel rollers resist corrosion in wet environments, while rubber-coated rollers provide grip for slippery metal surfaces. Custom spacing between rollers can accommodate the diameter of 3-gallon buckets, and modular designs allow easy integration into existing conveyor setups. Manufacturers often offer rollers with load capacities matching the weight of full metal buckets to prevent sagging or misalignment.

Q: How do pails buckets and 3 gallon metal buckets differ in roller compatibility?

A: Pails buckets come in various materials (plastic, metal) and sizes, so roller design must adapt—plastic pails may require gentle rollers to avoid scratching, while 3 gallon metal buckets need sturdy, abrasion-resistant rollers. Metal buckets’ rigidity allows use of heavier-duty rollers with higher load ratings, whereas flexible plastic pails might need rollers with cushioning to prevent deformation. Always match roller material and spacing to the bucket’s construction for optimal performance.

Q: What safety considerations apply when using bucket rollers with 3 gallon metal buckets?

A: When using bucket rollers with 3 gallon metal buckets, ensure rollers are grounded to prevent static buildup, especially if transporting flammable liquids. Install guards around rollers to prevent hands from getting caught, and use anti-tip mechanisms for inclined conveyors. Metal buckets can be heavy when full, so verify that rollers and their supports can handle the load to avoid collapse. Regular safety audits of roller systems help identify hazards like loose fasteners or misaligned tracks.

Welcome to Shijiazhuang Longzhitai Packaging—where 10 years of innovation meet infinite packaging possibilities! As a global leader in metal and compound solutions, we transform brands into tangible experiences through tinplate, aluminum, paper, and wooden packaging.

Our 5 automated lines and 160 artisans (20+ designers) craft 3M+ units monthly, blending lean manufacturing with bespoke creativity. From CAD-blueprinted tea tins to embossed chocolate containers, we mold your vision—literally. Need a heart-shaped caviar tin with 3D varnish or a recyclable pharmaceutical pack? Our in-house magic (hello, custom molds!) turns "impossible" into industry standards.

Eco-warriors rejoice: our infinitely recyclable metal packaging keeps sustainability stylish. Family-run passion meets tech-savvy production here—where every hinge, emboss, and screw-top is a love letter to your brand. Dive into endless shapes, finishes, and functions at www.packaging-help.com . Let’s package your story, together.

-

Small Square Tin Manufacturing Process

VijestiAug.11,2025

-

Design Ideas for Round Biscuit Tin Box

VijestiAug.11,2025

-

Design Ideas for Heart Box

VijestiAug.11,2025

-

Cost Analysis of Rectangle Tin Can

VijestiAug.11,2025

-

Choosing the Right Round Plastic Buckets

VijestiAug.11,2025

-

Applications of Pails Buckets

VijestiAug.11,2025