Чер . 08, 2025 18:04 Back to list

Custom Tin Packaging Durable & Eco-Friendly Solutions

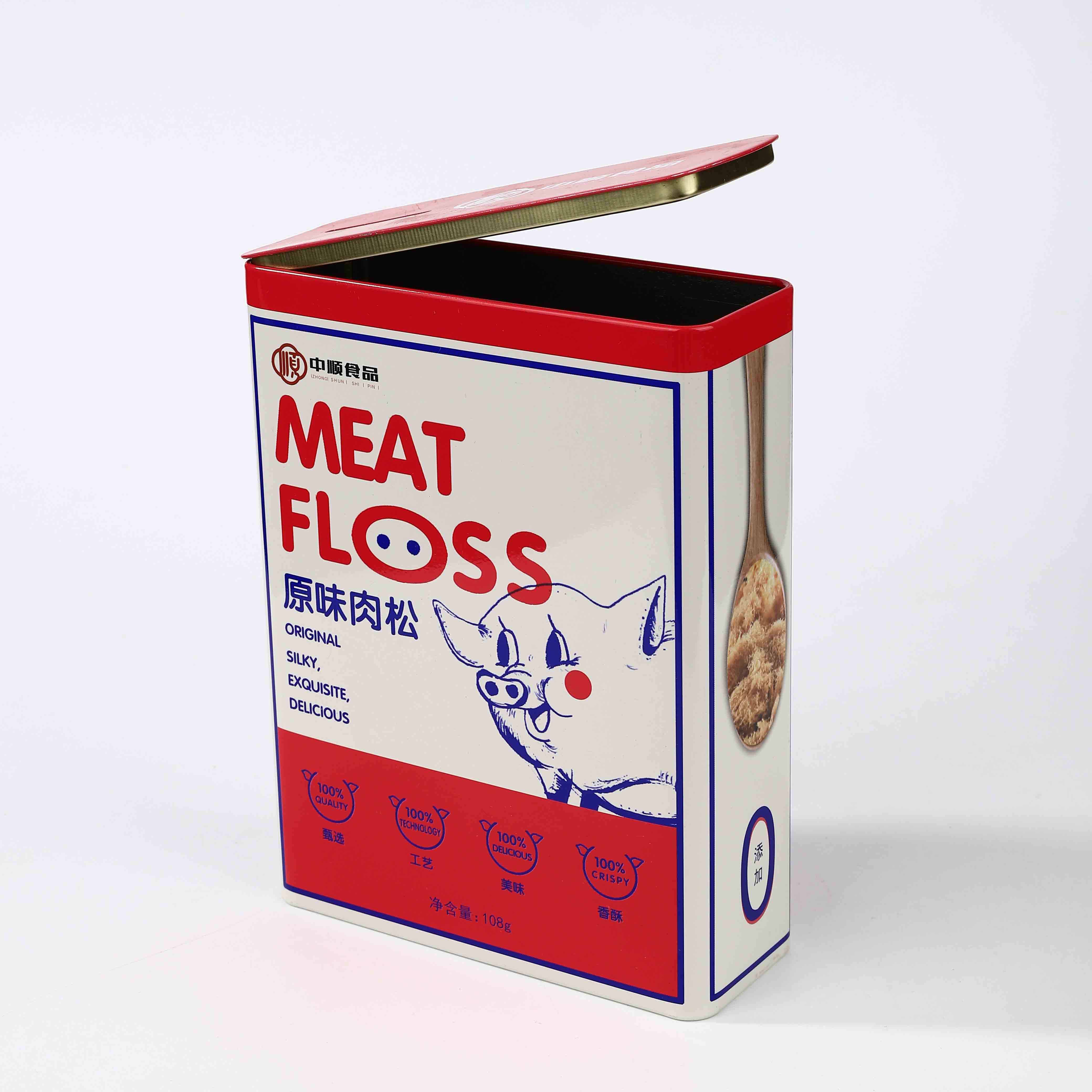

(tin package )

The Rising Demand for Tin Package Solutions

Global packaging demands have shifted significantly toward metal-based solutions, with tin packaging emerging as a premium choice for manufacturers requiring chemical stability and sustainability. Tin package products provide exceptional barrier protection against light, moisture, and oxygen, extending product shelf life by 20-40% compared to plastic alternatives. Industries ranging from premium foods to pharmaceuticals increasingly specify tin packaging for its superior product integrity and environmental profile.

Key considerations driving tin package

adoption:

- Annual industry growth: 6.2% CAGR forecast through 2029

- Recycling rate advantage: 72% for tin vs. 42% for composite materials

- Premium positioning: 64% of luxury goods buyers associate tin with quality

- Customization capacity: Design-to-production turnaround in 14 days minimum

Market Growth and Performance Metrics

The global tin packaging market reached $21.8 billion in 2023, driven by stringent food safety regulations and pharmaceutical packaging requirements. Sector-specific insights reveal confectionery dominates with 38% market share, followed by cosmetics (27%) and specialty foods (19%). Quality-conscious European manufacturers lead adoption rates at 78%, while North American markets show strongest growth potential at 8.9% annually. Supply chain disruptions during 2020-2022 prompted 54% of companies to diversify tin package factories, accelerating regional production capabilities.

Performance data highlights:

| Parameter | Standard Grade | Premium Food Grade | Pharma Grade |

|---|---|---|---|

| Oxygen Barrier | 0.05 cc/m²/day | 0.02 cc/m²/day | 0.005 cc/m²/day |

| Maximum Humidity Resistance | 85% RH | 95% RH | 99% RH |

| Production Speed (units/min) | 50 | 35 | 25 |

| Recycled Material Content | 25-40% | 15-25% | 5-15% |

Technological Advantages in Tin Packaging

Modern tin package factories utilize electrolytic chromium-coated steel (ECCS) that eliminates traditional tinplate's porosity issues. Advanced induction sealing technology creates hermetic seals capable of withstanding -40°C to 150°C thermal cycles. Leading facilities employ digital twin simulation during design phases, reducing prototyping costs by 62% and eliminating 98% of structural flaws before production. The most significant advancement involves nano-coating interiors that increase corrosion resistance 30-fold while meeting FDA direct-food-contact standards.

Intelligent production monitoring systems track these critical metrics:

- Seam integrity testing every 15 minutes

- Metal thickness consistency ±0.01mm

- Printing registration accuracy < 0.15mm

- Internal pressure testing to 200kPa minimum

Leading Manufacturer Capabilities Compared

When evaluating tin package factories, production capacity and certification levels create distinct competitive tiers:

| Supplier Class | Annual Capacity | Certifications | Minimum Order | Lead Time |

|---|---|---|---|---|

| Tier 1 Global | 50M+ units | BRCGS AA, ISO15378, FSSC22000 | 100,000 units | 8-10 weeks |

| Regional Specialists | 5-50M units | ISO9001, SEDEX | 25,000 units | 6-8 weeks |

| Custom Boutique | 500K-5M units | GMP, ISO14001 | 5,000 units | 4-6 weeks |

Specialty producers offer niche advantages: Japanese factories excel in precision printing for collectible tins, while German manufacturers lead in automated quality control systems. Labor costs create 15-22% price variations between regions, with Vietnamese factories offering best value for standard designs. Recent tariff structures increased Mexico's competitiveness for North American clients, with shipping times reduced to 8 days versus 28 days from Asia.

Customization Options and Process Flow

Tin package products transform from concept to finished goods through a defined customization workflow:

Stage 1: Design Consultation - Engineers evaluate structural requirements using CAD simulations. Typical considerations include stacking strength (minimum 300kg compressive load for shipping tins), opening mechanisms, and insert compatibility.

Stage 2: Tooling Development - High-precision molds manufactured to ±0.03mm tolerances, costing $6,000-25,000 depending on complexity. Lead times average 28 days.

Stage 3: Decoration Options - Choices include offset printing (8-color maximum), hot foil stamping, embossing depths to 1.2mm, and protective overvarnishes. Specialty finishes like matte textures or soft-touch coatings add 15-40% to decoration costs.

Stage 4: Value-Add Services - Assembly options such as interior flocking, ESD protection for electronics, or custom insert fabrication. Premium clients increasingly request NFC tag integration for smart packaging functionality.

Industry-Specific Implementation Case Studies

Luxury Tea Brand - A UK specialty company reduced packaging waste 70% by switching to rectangular tin packages with stackable designs. The custom-tooled containers feature friction-fit lids eliminating plastic seals. Production handled by a Portuguese factory specializing in thin-gauge metals.

Cosmeceutical Application - Korean skincare leader incorporated airless pump mechanisms into 50ml tin tubes that extend product efficacy by preventing oxidation. The factory implemented nitrogen flushing during filling for enhanced preservation.

High-Value Electronics - German sensor manufacturer adopted ESD-safe tin packages with conductive interior coatings. Containers withstand 100V electrostatic discharge while providing IP67 environmental protection. Weight savings versus aluminum alternatives cut shipping costs 19%.

Future Innovations in Tin Package Manufacturing

Next-generation tin package solutions will incorporate thinner gauge materials without compromising strength - 0.15mm prototypes already match 0.22mm standard performance. Sustainability initiatives focus on recycled content breakthroughs; experimental smelting techniques successfully reused 92% of post-consumer material while maintaining food-grade purity. Global tin package factories are transitioning to renewable-powered manufacturing, with three Scandinavian facilities already achieving carbon-neutral certification. Industry 4.0 integration enables real-time customization: clients can modify batch specifications mid-production based on IoT sensor feedback. Standard lead times are projected to compress 30% by 2026 through predictive maintenance systems and decentralized production hubs.

Chemical resistance parameters continue advancing, with new lacquering systems protecting contents against strong solvents. As premium brands compete for shelf impact, expect increased implementation of structural innovations like hinged designs and integrated lighting elements. The tin package industry's future remains secured by its unparalleled balance of aesthetics, functionality, and recyclability.

(tin package )

FAQS on tin package

Below is the HTML-formatted response with 5 groups of FAQs centered around the core keyword "tin package" and its related terms "tin package product," "tin package quotes," and "tin package factories." Each FAQ group consists of a question enclosed in an H3 tag starting with "Q:", and an answer starting with "A:", with all content restricted to a maximum of three sentences for brevity and clarity.Q: What is a tin package?

A: A tin package refers to a durable container made from tinplate or tin-coated steel, often used to preserve and protect products like food, gifts, or cosmetics. It provides excellent barrier properties against moisture and air to extend shelf life. Additionally, it's customizable for branding purposes.

Q: What are common tin package products?

A: Tin package products include items like tea tins, cookie boxes, beverage cans, and promotional gift sets. They are chosen for their aesthetic appeal and ability to maintain product freshness. These are widely used in industries such as food, beverages, and cosmetics.

Q: How do I obtain tin package quotes?

A: To get tin package quotes, request pricing from manufacturers by specifying details like size, quantity, and design. You can submit an online inquiry form on factory websites or contact them directly via email or phone. They'll provide a quote based on your custom requirements.

Q: How do I select reliable tin package factories?

A: Choose tin package factories based on their experience, production capacity, and quality certifications like ISO. Review customer testimonials and request samples to evaluate material and finish quality. Factory visits or virtual tours can also ensure they meet your standards.

Q: Are tin packages eco-friendly?

A: Yes, tin packages are sustainable as they are fully recyclable and reusable, reducing environmental waste. They often replace single-use plastics, conserving resources and lowering carbon footprint. Recycling programs help extend their lifecycle sustainably.

-

Large Metal Box Manufacturers: Durable & Custom Solutions for Industry

NewsJul.26,2025

-

High-Quality Steel Pail with Lid Manufacturers – Durable & Secure Storage Solutions

NewsJul.25,2025

-

High-Quality Steel Pail with Lid Manufacturers for Industrial Use

NewsJul.24,2025

-

Premium Round Cookie Tins Manufacturers – Custom Designs, Bulk Supply

NewsJul.23,2025

-

Top Large Metal Box Manufacturers: Durable Custom Solutions

NewsJul.22,2025

-

Premium Large Metal Box Manufacturers | Custom Solutions

NewsJul.21,2025