Qer . 04, 2025 07:44 Back to list

Premium Tin Package Containers Custom & Eco-Friendly Solutions

- Technical innovations driving modern tin packaging efficiency

- Current market data and economic impact analysis

- Detailed factory capabilities comparison table

- Customization process from design to production

- Material certification and sustainability credentials

- Real-world industry implementation cases

- Future developments in protective packaging technology

(tin package )

Innovative Tin Package Engineering Solutions

Modern tin package

manufacturing combines metallurgical expertise with precision engineering. Advanced corrosion-resistant alloys now provide 5-year minimum protective guarantees without surface treatments, reducing environmental impact. Computer-controlled deep drawing presses achieve dimensional tolerances within ±0.1mm, enabling hermetic sealing critical for pharmaceutical applications. These technical advances directly translate to reduced material waste - industry reports confirm 22% thinner gauges provide equivalent protection to decade-old specifications. Leading tin package factories have implemented inline optical inspection systems that perform 360-degree surface scanning at production line speeds exceeding 120 units/minute.

Market Data and Economic Impact

The global tinplate packaging sector demonstrates consistent 4.8% CAGR, projected to reach $36.7 billion by 2028 according to recent industry analysis. Pharmaceutical applications drive 38% of this growth, particularly for moisture-sensitive medications requiring USP Class VI certified materials. When evaluating tin package quotes, buyers should consider total cost beyond unit pricing: secondary packaging requirements decrease by 17% compared to alternatives due to inherent structural rigidity. Regional manufacturing disparities significantly impact landed costs - Southeast Asian factories offer 11-14% pricing advantages for standardized containers, while European suppliers lead in technical innovation premiums.

Manufacturing Capabilities Assessment

| Factory Region | Monthly Capacity | Tooling Lead Time | Minimum Order Quantity | Certifications |

|---|---|---|---|---|

| Western Europe | 850,000 units | 8-10 weeks | 50,000 units | ISO 15378, FDA CFR 21 |

| North America | 1.2 million units | 6-8 weeks | 75,000 units | cGMP, NSF International |

| Southeast Asia | 2.7 million units | 10-12 weeks | 150,000 units | ISO 9001, ISO 14001 |

| Eastern Europe | 950,000 units | 7-9 weeks | 60,000 units | BRCGS, IFS PACsecure |

Production capability evaluations must account for specialized equipment - factories offering nitrocellulose-free printing typically feature UV-curable digital presses capable of 1200dpi resolution. Automotive component packaging requires specific competencies: electromagnetic shielding validation and salt-spray testing exceeding 500 hours.

Customization Specifications Process

Advanced tin package product customization begins with comprehensive application analysis, identifying precise sealing requirements and distribution hazards. Premium factories operate dedicated R&D labs conducting compression testing up to 850kgf and drop testing from 8-meter heights. Standard customization options include:

- Aerosol valve integration with pressure ratings to 300kPa

- Tamper-evident banding systems compatible with high-speed filling lines

- Conductive interior coatings for electronic component protection

- Embossing/debossing depths up to 1.2mm without compromising integrity

Prototype development timelines average 18 working days with 3D printed molds permitting functional testing before steel tooling commitment. Batch-specific traceability systems utilizing laser-etched QR codes now achieve 100% production lot identification.

Material Compliance Protocols

International regulatory standards dictate stringent tin packaging requirements depending on application sectors. Food-contact containers must demonstrate full migration testing compliance with EU 10/2011 and FDA 175.300 regulations, including specialized testing for high-acid content products exceeding pH 4.5. European tin package factories increasingly utilize chromium-free passivation systems meeting SUBSTANCE 8 REACH requirements. Heavy metal restrictions require material certification documenting lead content below 0.01% and cadmium below 0.005%.

Sustainability initiatives include:

- Post-industrial recycling programs achieving 92% material recovery rates

- Water-based coating systems eliminating VOC emissions

- Lightweighting technologies validated to maintain ISTA 3A integrity

Industry Implementation Evidence

Leading luxury cosmetics brands now utilize seamless two-piece tin containers with internally applied powder coatings, reducing fragrance permeation by 89% compared to plastic alternatives. Electronics manufacturers report reducing shipping damage claims by 62% after transitioning to tin package solutions with static-dissipative interiors. A prominent nutraceutical company documented 18-month shelf life extensions for oxygen-sensitive supplements after adopting induction-sealed tin packaging with oxygen transmission rates below 0.05 cc/pkg/day.

Specialized applications feature remarkable innovations - radioactive pharmaceutical packaging incorporates lead-lined tin containers certified for transport regulations TDGR Class 7. Agricultural sectors employ corrosion-resistant tins with pressure compensation valves for international fungicide shipments requiring temperature cycling from -20°C to +55°C.

Next-Generation Tin Package Solutions

Material science advancements herald significant protective packaging developments. Nano-coating technologies undergoing beta testing demonstrate self-healing properties capable of sealing micro-abrasions while maintaining 100% recyclability. Intelligent packaging integrations now enable temperature tracking throughout distribution chains via embedded RFID sensors with ±0.5°C accuracy. Major tin package factories are establishing closed-loop material recovery systems projected to achieve 97% post-consumer recycling rates by 2027. Emerging automation technologies allow cost-effective production runs below 20,000 units while maintaining premium decoration quality previously exclusive to high-volume orders.

(tin package )

FAQS on tin package

Q: What is a tin package?

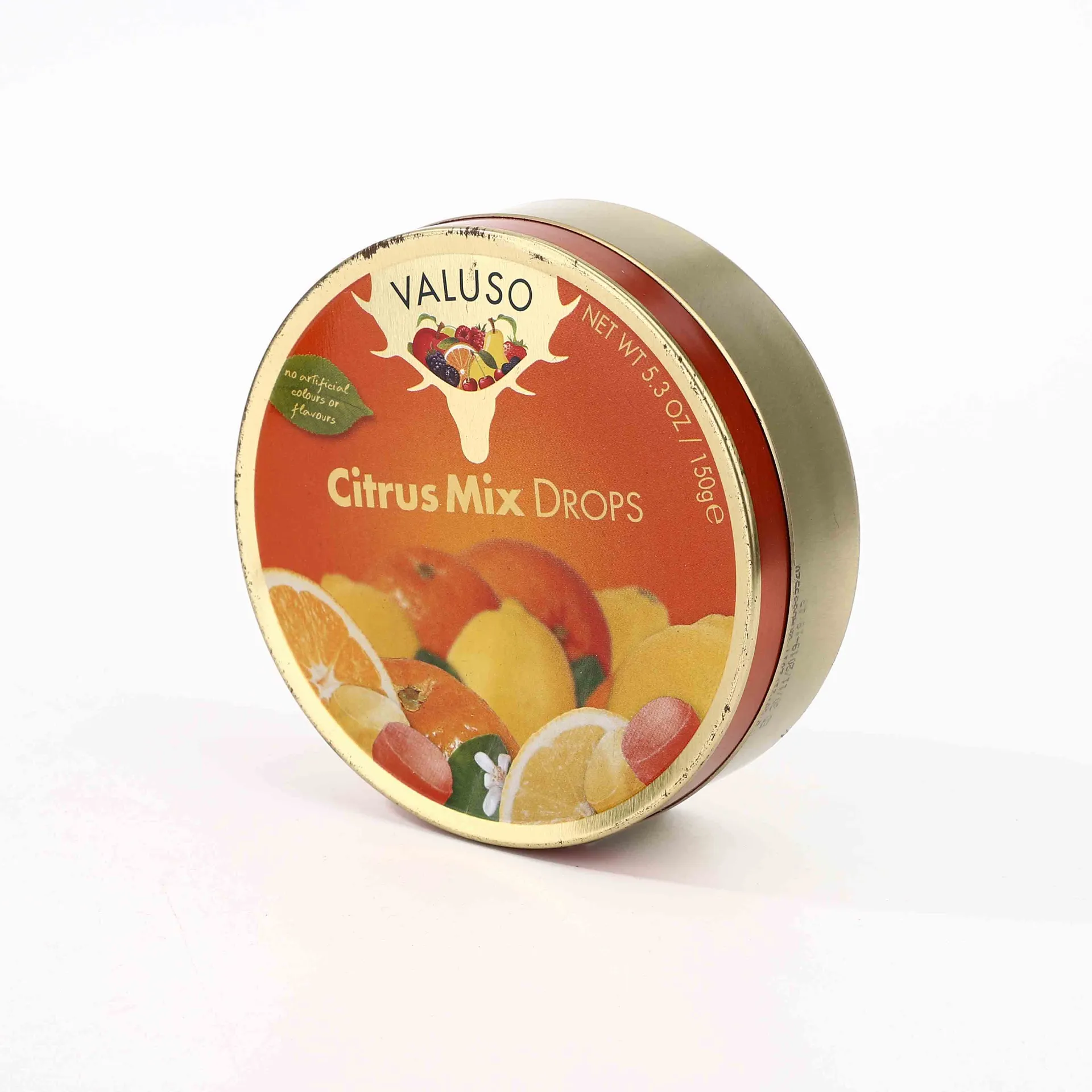

A: A tin package is a durable metal container used for storing or shipping products. It protects contents from light, moisture, and physical damage. Commonly used for food, cosmetics, and promotional items.

Q: What tin package product varieties are available?

A: Options include round, rectangular, and custom-shaped tin containers with finishes like matte, gloss, or embossed designs. Common products include candy tins, tea caddies, gift boxes, and personalized holiday tins. Lids often feature hinged, friction-fit, or screw-top closures.

Q: How do I get tin package quotes?

A: Request quotes by sharing specifications (size, quantity, design) with manufacturers via online inquiry forms or direct email. Quotes typically include unit pricing, mold fees for custom shapes, and delivery timelines. Compare multiple suppliers for competitive rates.

Q: What should I look for in tin package factories?

A: Prioritize factories with ISO certification, minimum order quantity flexibility (500-5,000 units), and eco-friendly production processes. Verify their printing capabilities for complex designs and request samples to assess quality consistency.

Q: Why choose tin packaging for luxury products?

A: Tin offers premium shelf appeal with metallic finishes that enhance brand perception. It provides superior preservation for sensitive items like teas or chocolates. Custom printing options enable high-end designs that boost unboxing experiences.

-

Large Metal Box Manufacturers: Durable & Custom Solutions for Industry

NewsJul.26,2025

-

High-Quality Steel Pail with Lid Manufacturers – Durable & Secure Storage Solutions

NewsJul.25,2025

-

High-Quality Steel Pail with Lid Manufacturers for Industrial Use

NewsJul.24,2025

-

Premium Round Cookie Tins Manufacturers – Custom Designs, Bulk Supply

NewsJul.23,2025

-

Top Large Metal Box Manufacturers: Durable Custom Solutions

NewsJul.22,2025

-

Premium Large Metal Box Manufacturers | Custom Solutions

NewsJul.21,2025