Dec . 19, 2024 17:44 Back to list

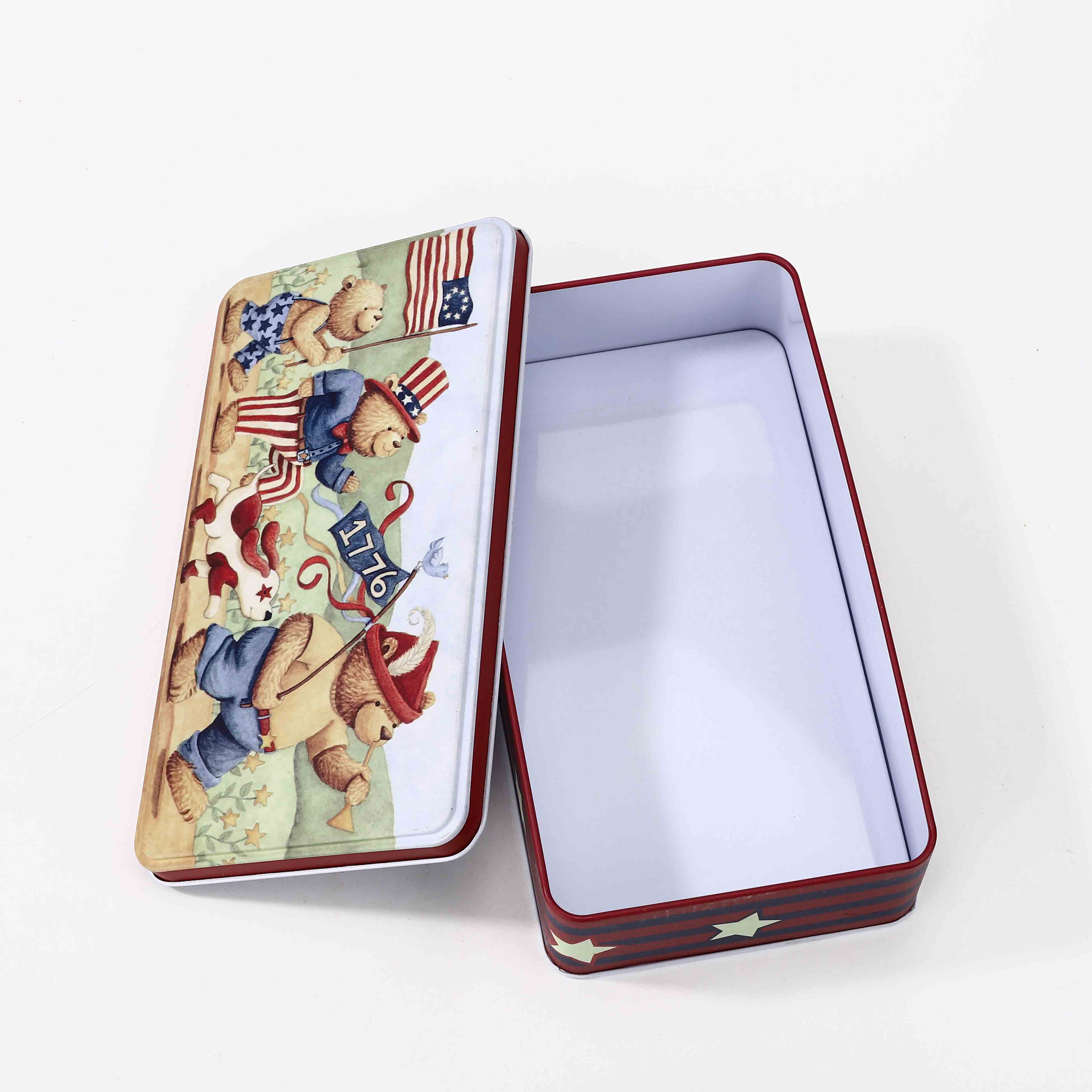

custom rectangular tin box production for various packaging needs

Exploring the World of Rectangular Tin Box Manufacturers

In today’s fast-paced consumer market, packaging plays a pivotal role in product presentation, preservation, and functionality. Among the various materials used for packaging, tin has emerged as a preferred choice due to its durability, recyclability, and aesthetic appeal. Rectangular tin boxes, in particular, have gained immense popularity across different industries, leading to a burgeoning market for rectangular tin box manufacturers.

The Importance of Rectangular Tin Boxes

Rectangular tin boxes are versatile containers used for packaging a wide range of products. From confectionery and tea to cosmetics and tools, these boxes are highly favored for their ability to protect contents from environmental factors such as moisture, light, and air. This protection helps prolong the shelf life of products, making them an ideal choice for manufacturers who prioritize quality and customer satisfaction.

Moreover, rectangular tin boxes offer ample surface area for branding and design. This characteristic allows companies to create visually appealing packaging that can attract consumers' attention on store shelves. Effective branding through creative designs can significantly influence purchasing decisions, which is why many brands invest in high-quality tin packaging.

The Role of Manufacturers

Rectangular tin box manufacturers play a crucial role in the supply chain by providing these packaging solutions to various industries. The manufacturing process involves several steps that begin with sourcing high-quality materials. Tinplate, a thin sheet of steel coated with tin, is commonly used in the production of tin boxes due to its strength and resistance to corrosion.

Once the raw materials are procured, manufacturers utilize advanced machinery and techniques to shape, cut, and mold the tin into rectangular boxes. This process can involve stamping, welding, and printing, allowing for custom designs and sizes tailored to specific client needs. Many manufacturers offer services that encompass everything from initial design concepts to the final product, ensuring a seamless experience for their customers.

Innovation and Customization

rectangular tin box manufacturer

In recent years, the demand for tailored solutions has prompted manufacturers to innovate and expand their offerings. Customization options, such as size variations, colors, finishes, and printing techniques, have become essential services. Manufacturers now frequently collaborate with clients to create unique packaging that aligns with their brand identity and market positioning.

Furthermore, sustainability has emerged as a key trend in packaging. As consumers become increasingly environmentally conscious, manufacturers are exploring ways to produce tin boxes that meet eco-friendly standards. This includes utilizing recycled materials, reducing waste in the manufacturing process, and promoting the recyclability of tin boxes. Through these efforts, manufacturers not only appeal to eco-conscious consumers but also contribute to a greener planet.

Market Trends and Challenges

The global market for rectangular tin boxes is projected to grow significantly in the coming years. Factors contributing to this growth include rising demand in sectors such as food and beverage, cosmetics, and specialty goods. E-commerce has also played a vital role, as more businesses seek durable and attractive packaging to engage customers online.

However, manufacturers face challenges such as fluctuating raw material costs, competition from alternative packaging options, and the need to continually innovate in design and functionality. To remain competitive, manufacturers must adapt to changing market trends while ensuring high-quality products and efficient production processes.

Conclusion

Rectangular tin box manufacturers are at the forefront of the packaging industry, providing essential solutions that combine functionality with aesthetic appeal. As the demand for customizable and sustainable packaging continues to rise, these manufacturers are well-positioned to meet the evolving needs of businesses across various sectors. By focusing on innovation, quality, and customer collaboration, rectangular tin box manufacturers play a vital role in enhancing product presentation and functionality in today’s marketplace.

In conclusion, as the packaging landscape evolves, the significance of rectangular tin boxes and the manufacturers behind them will only grow, helping businesses stand out and ensuring that their products remain protected and appealing in a competitive market.

-

Leading Large Metal Box Manufacturers | Custom Solutions

NewsAug.04,2025

-

Top Steel Pail with Lid Manufacturers | Rust-Proof

NewsAug.03,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.02,2025

-

Top Metal Box Manufacturers | Custom Solutions

NewsAug.01,2025

-

Top Large Metal Box Manufacturers | Durable & Custom Solutions

NewsJul.31,2025

-

Top Steel Pail with Lid Manufacturers | Custom Industrial

NewsJul.31,2025