Nov . 09, 2024 16:46 Back to list

Tin Can Solutions for Efficient Food Preservation in Canning Industries

The Role of Tin Cans in Canning Factories

In the world of food preservation and packaging, tin cans have played a pivotal role in ensuring freshness, safety, and convenience. Canning factories rely heavily on these metallic containers for a multitude of reasons, making them an essential component of the food processing industry. This article explores the significance of tin cans in canning factories, delving into their history, advantages, production processes, and future prospects.

Historically, the invention of the tin can dates back to the early 19th century. The process began when food preservation methods were limited, and the need for longer shelf life became apparent. The first canned foods were produced in France in 1810, and the technology quickly spread across Europe and America. Today, tin cans are synonymous with canning, having evolved into a primary method for preserving food and beverages.

The Role of Tin Cans in Canning Factories

The production of tin cans involves several intricate steps, starting from the sourcing of raw materials. Cans are typically made from steel sheets that are coated with a thin layer of tin to prevent rusting and corrosion. This process also enhances the can's protective qualities. Inside the can, a food-grade lacquer is often applied to ensure that the food does not react with the metal, thus maintaining flavor and safety.

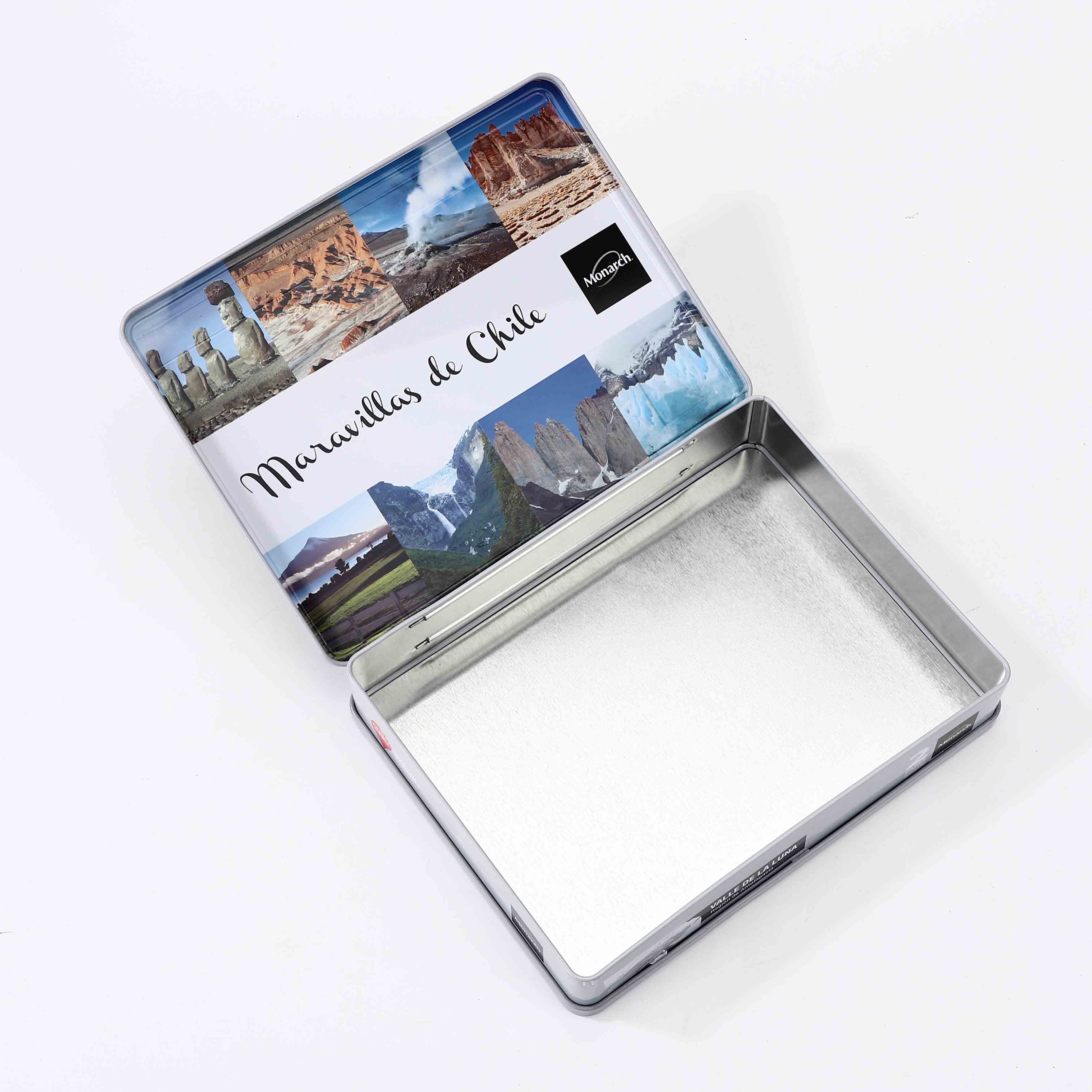

tin cans for canning factories

In a modern canning factory, the production process is highly automated, incorporating advanced technologies that optimize efficiency. First, the metal sheets are cut into the required shapes and then formed into cylinder shapes to create the can body. Next, the ends are attached, and the cans go through rigorous quality control checks to ensure they meet safety and quality standards. Afterward, the cans are filled with food products, sealed, and then subjected to heat treatment to kill any bacteria.

Canning factories also benefit from the sustainability aspect of tin cans. They are 100% recyclable and can be recycled indefinitely without losing quality. This feature aligns well with the growing demand for eco-friendly packaging solutions. Many consumers today are increasingly aware of their choices and prefer products that contribute to reducing waste and promoting a sustainable environment. As a result, canning factories that utilize tin cans can appeal to this conscientious consumer base.

The future of tin cans in canning factories looks promising, with ongoing innovations focused on improving their design and functionality. For instance, advancements in can coatings are being developed to enhance their resistance to corrosion and improve the overall safety of canned foods. Additionally, manufacturers are exploring ways to incorporate smart technology, such as QR codes, to provide consumers with detailed information about the product’s origin, nutritional content, and expiration dates.

Moreover, as global food production continues to grow, the demand for efficient preservation methods will likely rise as well. Tin cans, with their established benefits, are positioned well to meet these needs, providing a robust solution for both manufacturers and consumers alike.

In conclusion, tin cans are fundamental to the operations of canning factories. Their historical significance, combined with a host of advantages such as durability, safety, and sustainability, solidifies their essential role in the food packaging industry. As technology advances and sustainability becomes a focal point of consumer demand, tin cans will likely continue to evolve, ensuring that they remain a relevant and vital component of food preservation for years to come.

-

Large Metal Box Manufacturers | Custom & Durable Industrial Solutions

NewsAug.26,2025

-

Large Metal Box Manufacturers | Custom, Durable Solutions

NewsAug.25,2025

-

Large Metal Box Manufacturers: Custom, Durable Industrial Solutions

NewsAug.24,2025

-

Large Metal Box Manufacturers | Custom, Durable & Reliable

NewsAug.23,2025

-

Custom Large Metal Box Manufacturers & Suppliers | Durable Solutions

NewsAug.22,2025

-

Top Steel Pail with Lid Manufacturers - Durable & Secure

NewsAug.19,2025