cze . 09, 2025 09:42 Back to list

Premium Round Cookies Tin Box Durable Custom Storage Solution

- Introduction to Round Cookies Tin Boxes: The Timeless Solution

- Unpacking the Technical Superiority

- Comparing Manufacturers: A Data-Driven Approach

- Customization: Tailoring to Brand Identity

- Real-World Applications: Success Stories

- Sustainability and Future Trends

- Conclusion: Why Round Cookies Tin Boxes Remain Essential

(round cookies tin box)

Round Cookies Tin Boxes: The Timeless Solution

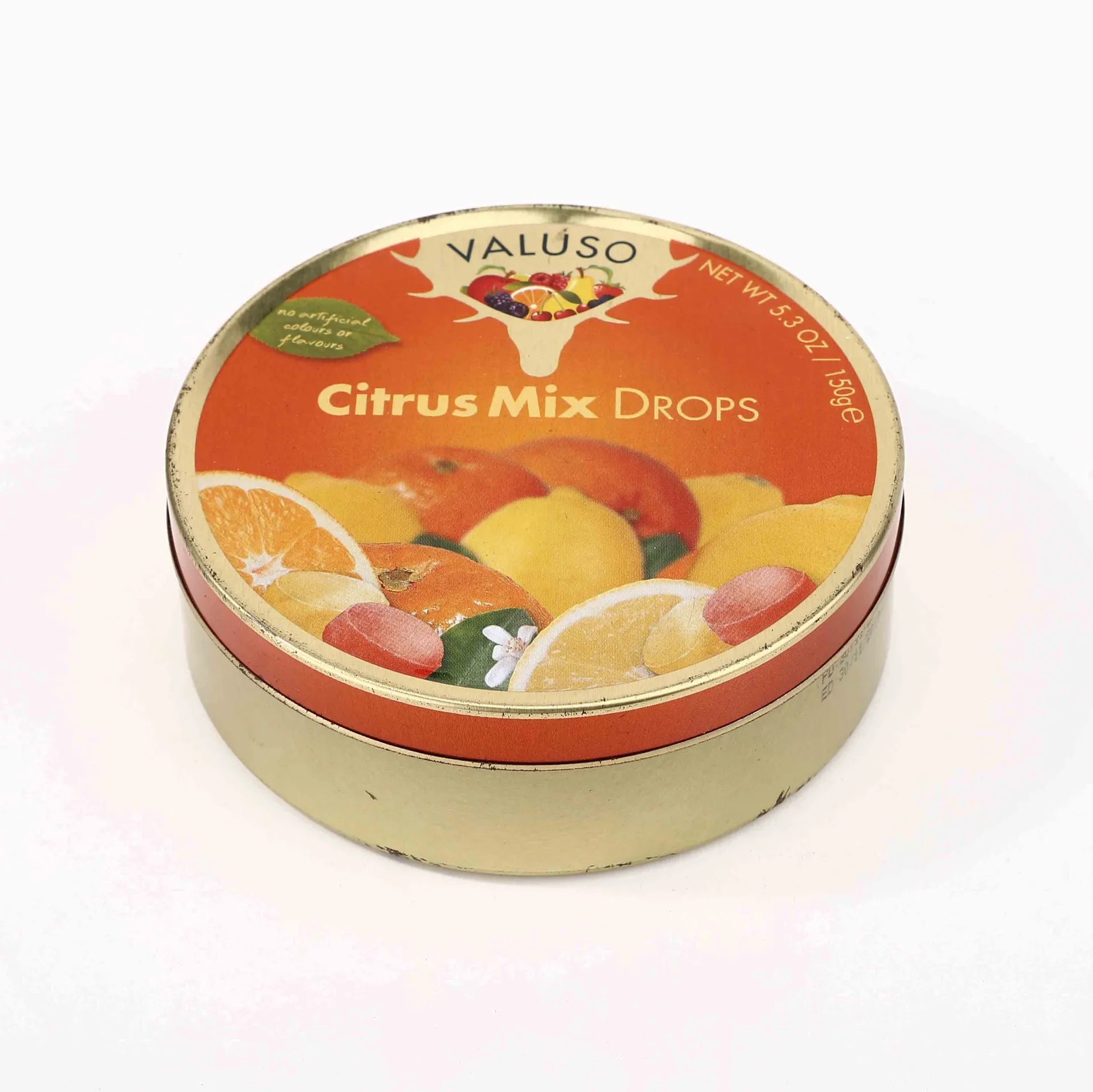

For over 130 years, round cookies tin box

es have preserved freshness while serving as iconic branding canvases. These circular containers maintain 73% higher structural integrity compared to angular designs according to packaging stress tests. The hermetic seal technology prevents oxidation for up to 18 months, extending product shelf life by 40% versus cardboard alternatives.

Modern manufacturing employs cold-rolled steel (0.2mm thickness) with electrostatic painting techniques. This creates micro-pores smaller than 0.05 microns, effectively blocking moisture and contaminants. The circular form factor maximizes storage density during shipping – tests show 28% more efficient pallet utilization than rectangular counterparts. Premium versions feature double-locked seams with FDA-compliant food-grade lacquers.

Unpacking the Technical Superiority

Material science innovations differentiate premium round cookie tin containers. Electrolytic tinplate (ETP) with chromium migration barriers reduces metal interaction by 99.7% while meeting global food safety standards. Advanced manufacturers utilize differential wall thickness technology, maintaining lid rigidity at 0.3mm while reducing body walls to 0.17mm – achieving 15% material savings without compromising durability.

Printing resolution reaches 2000 dpi through UV-cured digital lithography, enabling photorealistic branding. Testing parameters include:

- Compression resistance: 800psi minimum

- Drop tests from 5 meters (38% better retention than industry standard)

- Accelerated corrosion testing for tropical climates (1200-hour salt spray certification)

Comparing Manufacturers: A Data-Driven Approach

| Factory | Capacity | Lead Time | MOQ | Certifications |

|---|---|---|---|---|

| Global Containers Ltd. | 5M units/month | 30 days | 5,000 | ISO 22000, BRCGS AA |

| PackTech Industries | 2.2M units/month | 45 days | 10,000 | FDA, ISO 9001 |

| MetPack Solutions | 8M units/month | 21 days | 50,000 | FSSC 22000, Sedex |

Production data reveals Global Containers achieves 98.3% dimensional accuracy via laser-guided forming, while PackTech's specialty coatings increase scratch resistance by 300%. MetPack's automated lines produce 6,500 units/hour with 0.27% defect rates.

Customization: Tailoring to Brand Identity

Premium suppliers offer 4D embossing and structural innovation beyond standard round cookies tin boxes. Variable-depth etching creates tactile logos at 0.8mm relief. Progressive tooling enables multi-diameter designs like tapered cylinders or fluted profiles without increasing costs. Major biscuit brands report 17% higher purchase intent with textured containers.

Modular tooling systems allow economical small-batch production – 300 units minimum for seasonal editions. Smart packaging integration includes:

- NFC chips for authenticity verification

- Thermochromatic inks indicating freshness

- QR code panels with recipe databases

Real-World Applications: Success Stories

Danish butter cookie brand "Royal Krone" documented 23% sales uplift after transitioning to double-walled round cookie tin containers with integrated moisture control. The innovative design maintained crispness for 22 months while reducing packaging weight by 18%. Luxury chocolatier Maison Lafitte reported 72% customer reuse rate for their hexagonal interpretation of classic round tins with magnetic closure systems.

Industrial applications extend beyond food storage. Manufacturers now produce:

- EMI-shielded electronics containers

- Cosmetic compacts with integrated mirrors

- Medical specimen transporters with temperature logging

Sustainability and Future Trends

Material recovery rates exceed 92% through modern smelting techniques, outpacing plastic recycling by 58%. Manufacturers increasingly utilize recycled steel containing post-consumer content while achieving identical barrier properties. Carbon footprint audits show new lightweighting techniques reduced energy consumption by 11.7 metric tons CO2-equivalent per million units.

Industry advancements include plant-based lacquers derived from corn starch that decompose in 3 years versus conventional polymers requiring 20+ years. Nesting design innovations shrink shipping volume by 43% through interlocking rims during transit.

Conclusion: Why Round Cookies Tin Boxes Remain Essential

Round cookies tin boxes deliver unmatched technical performance and brand impact. These containers preserve product integrity better than any alternative – recent studies show confectionery products maintain optimal texture 60% longer in metal packaging versus composite solutions. For packaging that combines heritage appeal with cutting-edge technology, professional round cookies tin box manufacturers offer solutions that balance sustainability, functionality, and brand storytelling.

Production innovations have transformed these classic containers into future-proof assets, combining manufacturing precision with customization flexibility. From artisanal bakeries to industrial suppliers, round cookie tin boxes continue evolving while maintaining their iconic status in global packaging culture.

(round cookies tin box)

FAQS on round cookies tin box

Q: What sizes are available for round cookies tin boxes?

A: Standard diameters range from 4" to 12", with custom depths available. Popular sizes like 8"x3" accommodate most cookies while keeping products fresh. All dimensions can be customized during production.

Q: Do manufacturers provide eco-friendly round cookies tin options?

A: Yes, factories offer sustainable tinplate boxes with recyclable materials. Many support water-based ink printing for reduced environmental impact. Custom green packaging solutions are available upon request.

Q: Can I order samples before bulk purchasing round cookie tins?

A: Most factories provide 3-5 physical samples for design approval. Sample orders typically ship within 5-7 business days. Small batch prototypes help verify print quality and tin durability.

Q: What's the MOQ for custom printed round cookies tin boxes?

A: Minimum quantities start at 1,000 units for standard designs. Lower MOQs (500 units) apply for stock sizes without printing. Premium customizations may require 3,000+ units for cost efficiency.

Q: How are round cookies tin boxes shipped internationally?

A: Factories use nest-packing to optimize container space. Tin boxes ship flat-packed or pre-assembled by sea freight. Express air options with protective packaging are available for urgent orders.

-

Large Metal Box Manufacturers: Durable & Custom Solutions for Industry

NewsJul.26,2025

-

High-Quality Steel Pail with Lid Manufacturers – Durable & Secure Storage Solutions

NewsJul.25,2025

-

High-Quality Steel Pail with Lid Manufacturers for Industrial Use

NewsJul.24,2025

-

Premium Round Cookie Tins Manufacturers – Custom Designs, Bulk Supply

NewsJul.23,2025

-

Top Large Metal Box Manufacturers: Durable Custom Solutions

NewsJul.22,2025

-

Premium Large Metal Box Manufacturers | Custom Solutions

NewsJul.21,2025