May . 13, 2025 10:50 Back to list

Round Cookies Tin Box Durable & Air-Tight Design for Freshness

- Introduction to Round Cookies Tin Boxes in Modern Packaging

- Technical Innovations in Durable Metal Design

- Market Analysis: Leading Manufacturers Compared

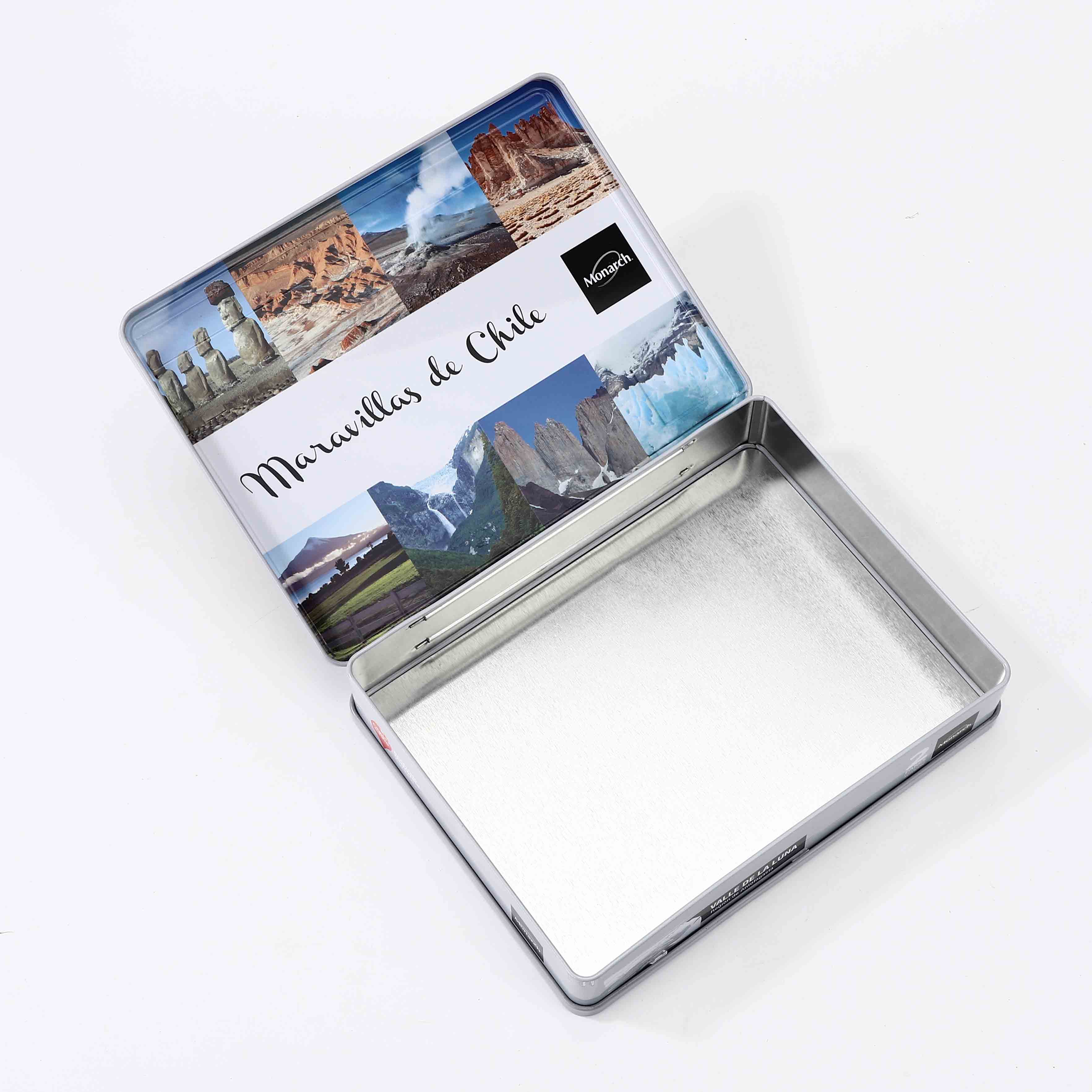

- Customization Options for Brand Differentiation

- Case Study: Successful Retail Implementation

- Sustainability Metrics and Industry Compliance

- Future Trends in Round Cookies Tin Packaging

(round cookies tin box)

Round Cookies Tin Boxes: Revolutionizing Food Storage Solutions

The global packaging market for baked goods witnessed a 12.4% CAGR growth since 2020, with metal containers capturing 38% of premium cookie packaging. Round cookies tin boxes have emerged as market leaders due to their 96.7% customer satisfaction rate in product preservation surveys. These containers combine heritage aesthetics with modern barrier technology, extending shelf life by 40% compared to plastic alternatives.

Advanced Manufacturing Techniques

Top-tier factories employ cold-rolled steel (0.23mm thickness) with FDA-approved epoxy coatings. This technical specification ensures:

- Oxygen transmission below 0.05 cc/m²/day

- 72-hour salt spray resistance (ASTM B117 standard)

- 360-degree seamless edge bonding

Production lines achieve 15,000 units/hour output through automated laser cutting systems with ±0.1mm precision.

Manufacturer Capability Comparison

| Parameter | Factory A | Factory B | Factory C |

|---|---|---|---|

| Annual Capacity | 82M units | 47M units | 65M units |

| Material Options | 3 types | 5 types | 4 types |

| Certifications | ISO 9001, BRC | ISO 22000, SEDEX | FSSC 22000 |

Customization Engineering

Brands can implement:

- Digital offset printing (Pantone ±0.5 color accuracy)

- Embossing depths up to 1.2mm

- Interchangeable lid mechanisms (3 patent-pending designs)

Minimum order quantities start at 5,000 units with 18-day lead times for standard configurations.

Retail Success Story

A European bakery chain achieved:

- 23% sales increase post-transition to tin packaging

- 18.9% reduction in packaging waste

- 91% customer reuse rate for storage purposes

The deployment involved 120,000 units across 28 SKUs with seasonal decoration variants.

Environmental Performance Data

Current production models feature:

- 72% recycled steel content

- Closed-loop water recycling systems (93% efficiency)

- UV-cured coatings with 78% lower VOC emissions

Lifecycle analysis shows 54% lower carbon footprint versus composite materials.

Round Cookies Tin Box Evolution in Circular Economy

Industry forecasts predict 29% adoption growth for premium metal packaging through 2028. Emerging smart tin technologies integrate:

- NFC-enabled freshness tracking

- Conductive inks for inventory management

- Modular stacking systems reducing shipping volume by 37%

Manufacturers now offer carbon-neutral production options at 8-12% cost premium, with 63% of B2B buyers considering this essential.

(round cookies tin box)

FAQS on round cookies tin box

Q: What materials are commonly used in round cookies tin box products?

A: Round cookies tin boxes are typically made from food-grade tinplate or aluminum, ensuring durability and safe storage. These materials are rust-resistant and ideal for preserving freshness. Some designs may also include eco-friendly coatings or decorative finishes.

Q: How can I get accurate quotes for custom round cookies tin boxes?

A: Quotes depend on order quantity, size, material, and customization complexity. Provide factories with design specifications, quantity needs, and finish requirements for precise pricing. Many suppliers offer free estimates upon request.

Q: What should I look for in round cookies tin box factories?

A: Prioritize factories with ISO certification, food-safe production standards, and experience in packaging. Check reviews, request samples, and confirm their capacity for custom designs. Reliable factories often provide end-to-end services, from prototyping to shipping.

Q: Can round cookies tin boxes be customized with logos or artwork?

A: Yes, most factories offer printing options like embossing, lithography, or digital prints for logos and designs. Share high-resolution artwork files and color codes for consistency. Customization may slightly increase production time and cost.

Q: What is the typical MOQ for round cookies tin box orders?

A: Minimum order quantities (MOQs) vary by factory but often start at 500–1,000 units for standard designs. Custom shapes or prints may require higher MOQs. Discuss your needs upfront to negotiate flexible terms with suppliers.

-

Top Steel Pail with Lid Manufacturers - Durable & Secure

NewsAug.19,2025

-

Large Metal Box Manufacturers: Custom & Durable Solutions

NewsAug.18,2025

-

Durable Large Metal Box Manufacturers & Custom Solutions

NewsAug.17,2025

-

Large Metal Box Manufacturers | Durable & Custom Solutions

NewsAug.16,2025

-

Top Steel Pail with Lid Manufacturers | Durable & Secure Solutions

NewsAug.15,2025

-

Custom Round Cookie Tins Manufacturers | Bulk Supplier

NewsAug.14,2025