Feb . 02, 2025 04:01 Back to list

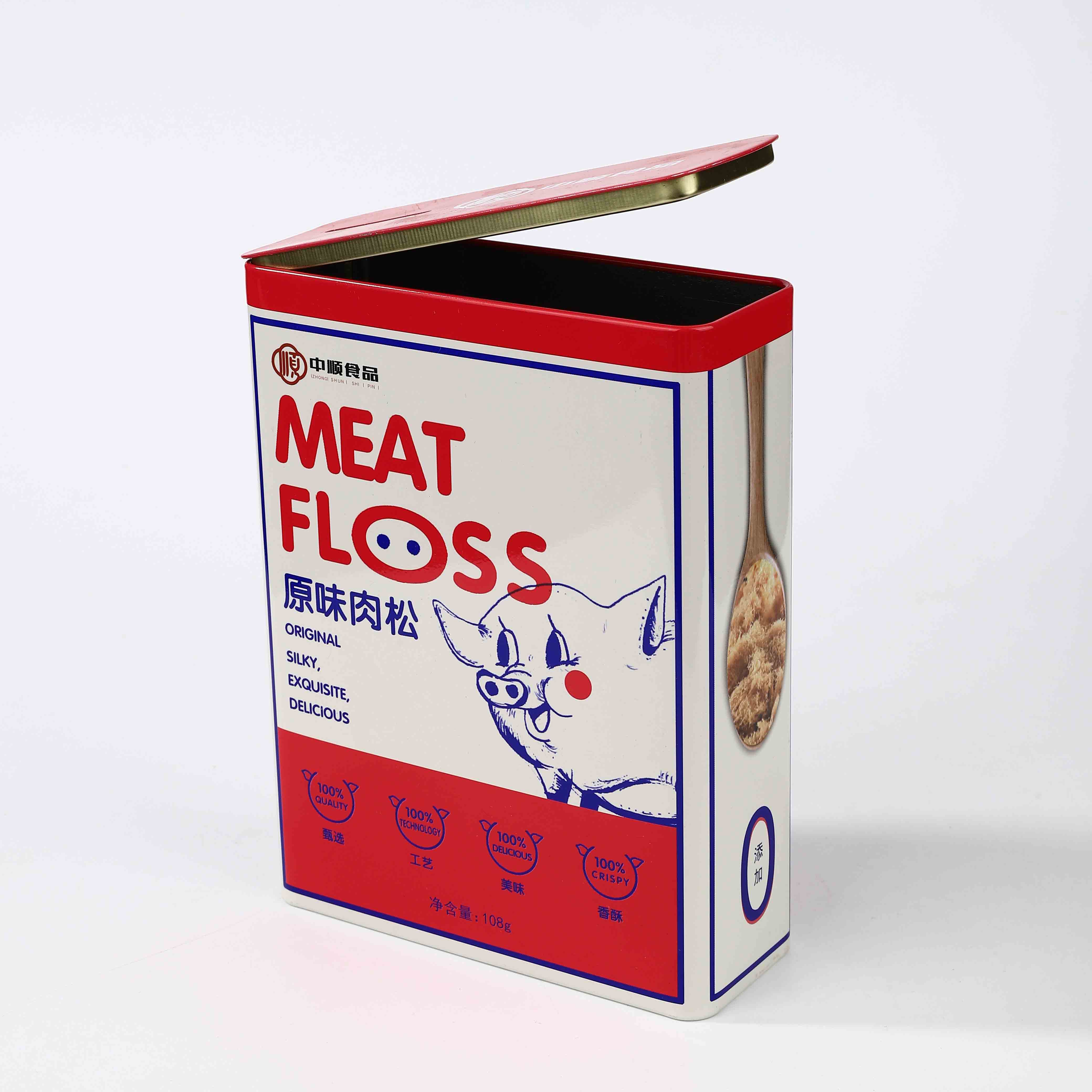

large metal box products

White tin, an often overlooked yet vital component in various industries, stands out due to its unique properties and versatility. Its importance spans across sectors such as electronics, food manufacturing, and even art restoration. Delving into the characteristics and applications of white tin will uncover why it's an indispensable material for specialized uses.

In terms of economic impact, the demand and supply dynamics of white tin are carefully monitored by industry experts. The metal's price can be influenced by mining operations, geopolitical factors, and technological advancements. Industry professionals must stay informed about these trends to make strategic decisions in production and investment. When discussing white tin, its safety and regulatory standards cannot be overlooked. With stringent guidelines governing its use, compliance with international standards ensures that products meet safety and quality benchmarks. This is particularly important in applications involving direct consumer contact, such as packaging and electronics. For businesses looking to differentiate themselves, understanding and leveraging the unique benefits of white tin can lead to innovative product developments and market differentiation. By strategically integrating white tin into their processes, companies can enhance product durability, safety, and sustainability, appealing to eco-conscious consumers and those seeking high-quality, reliable goods. Overall, white tin's versatility and range of applications highlight its critical role in modern manufacturing and beyond. Its unique properties not only contribute to improved product performance and durability but also reflect a broader commitment to quality, consumer safety, and environmental responsibility. Therefore, staying informed on advancements in the use of white tin will be essential for industry leaders aiming to remain at the forefront of innovation and sustainability.

In terms of economic impact, the demand and supply dynamics of white tin are carefully monitored by industry experts. The metal's price can be influenced by mining operations, geopolitical factors, and technological advancements. Industry professionals must stay informed about these trends to make strategic decisions in production and investment. When discussing white tin, its safety and regulatory standards cannot be overlooked. With stringent guidelines governing its use, compliance with international standards ensures that products meet safety and quality benchmarks. This is particularly important in applications involving direct consumer contact, such as packaging and electronics. For businesses looking to differentiate themselves, understanding and leveraging the unique benefits of white tin can lead to innovative product developments and market differentiation. By strategically integrating white tin into their processes, companies can enhance product durability, safety, and sustainability, appealing to eco-conscious consumers and those seeking high-quality, reliable goods. Overall, white tin's versatility and range of applications highlight its critical role in modern manufacturing and beyond. Its unique properties not only contribute to improved product performance and durability but also reflect a broader commitment to quality, consumer safety, and environmental responsibility. Therefore, staying informed on advancements in the use of white tin will be essential for industry leaders aiming to remain at the forefront of innovation and sustainability.

Latest news

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025

-

Leading Large Metal Box Manufacturers | Custom Solutions

NewsAug.04,2025

-

Top Steel Pail with Lid Manufacturers | Rust-Proof

NewsAug.03,2025