Aug . 12, 2024 10:26 Back to list

Top Manufacturers of Metal Pails and Buckets for Various Industrial Applications

The Evolution and Significance of Metal Pails and Buckets in Manufacturing

Metal pails and buckets have long been essential tools in a variety of industries, ranging from agriculture and construction to food processing and chemical handling. These robust containers are revered for their durability, versatility, and reliability. They not only serve practical purposes but also reflect the evolution of manufacturing processes and materials over the years.

Historical Context

The history of metal pails and buckets can be traced back centuries. Originally crafted by skilled artisans, these containers were made from wood and later transitioned to metals such as tin, steel, and aluminum. The introduction of metal into manufacturing heralded a new era, allowing for a wider range of applications. Metal pails became commonplace in household settings, commercial kitchens, and industrial workplaces due to their strength and ability to contain a variety of substances.

Manufacturing Processes

The modern manufacturing of metal pails and buckets involves advanced techniques, which enhance their functionality and extend their lifespan. The process typically begins with the selection of raw materials, often focusing on high-quality metals that resist corrosion and wear. Technologies such as electroplating, galvanizing, and powder coating are employed to improve these containers' durability and aesthetic appeal.

In recent years, innovations in manufacturing processes have also led to the development of eco-friendly options. Manufacturers are increasingly focusing on sustainable practices, utilizing recycled metals and reducing waste in production. This not only addresses environmental concerns but also resonates with consumers who are more eco-conscious than ever.

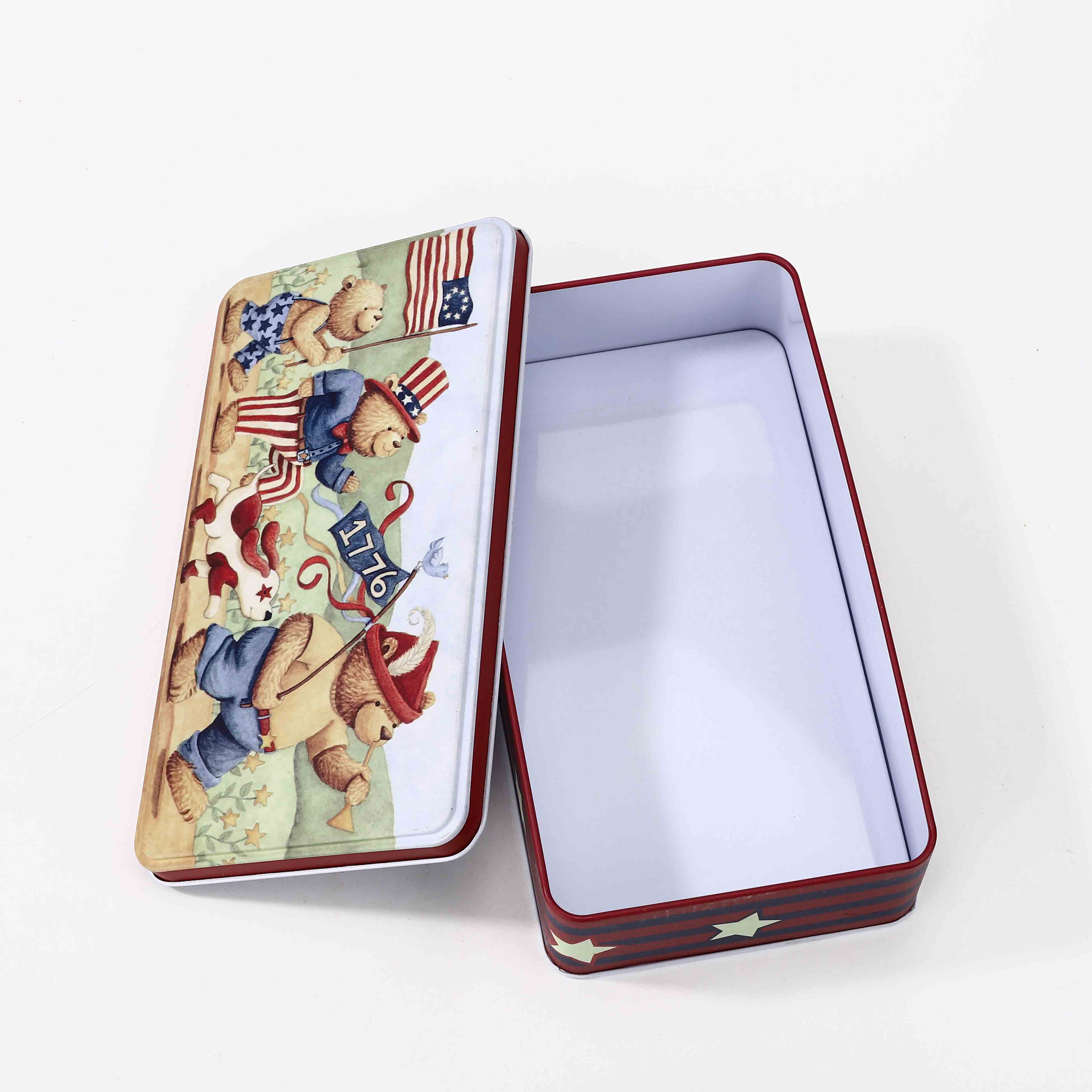

metal pails buckets manufacturers

Diverse Applications

The applications of metal pails and buckets are vast and varied. In agriculture, for instance, these containers are essential for transporting feed, water, and other materials. The construction industry relies on them for transporting tools, chemicals, and concrete. In food processing, metal buckets are often used for carrying ingredients or finished products, providing a hygienic solution that meets health and safety regulations.

Moreover, metal pails and buckets are indispensable in the chemical industry, where they commonly store hazardous substances. Their robust construction and secure sealing mechanisms mitigate the risk of spills and contamination, making them a safe option for transporting and storing chemicals.

Customization and Design

As the market for metal pails and buckets grows, manufacturers are responding to the demand for customization. Businesses often require containers that cater to specific sizes, shapes, and functionalities. Many manufacturers now offer personalized solutions, allowing clients to choose everything from the material to the color and labeling. This flexibility not only enhances brand visibility but also ensures that the products meet specific operational needs.

Conclusion

In conclusion, metal pails and buckets are far more than mere containers; they are integral components of various industries, reflecting advancements in manufacturing and design. The transition from traditional methods to modern manufacturing practices showcases the evolution of these vital tools. With continued innovations and a focus on sustainability, the future of metal pails and buckets appears bright. As manufacturers evolve to meet changing consumer needs, these sturdy containers will undoubtedly remain a cornerstone of industrial and commercial activities for years to come. Through their durability and versatility, metal pails and buckets will continue to support businesses in efficiently managing their operations while adapting to the ever-changing landscape of manufacturing.

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025

-

Leading Large Metal Box Manufacturers | Custom Solutions

NewsAug.04,2025

-

Top Steel Pail with Lid Manufacturers | Rust-Proof

NewsAug.03,2025