Oct . 22, 2024 06:08 Back to list

tin can manufacturers pricelist

Understanding the Pricing Dynamics of Tin Can Manufacturers

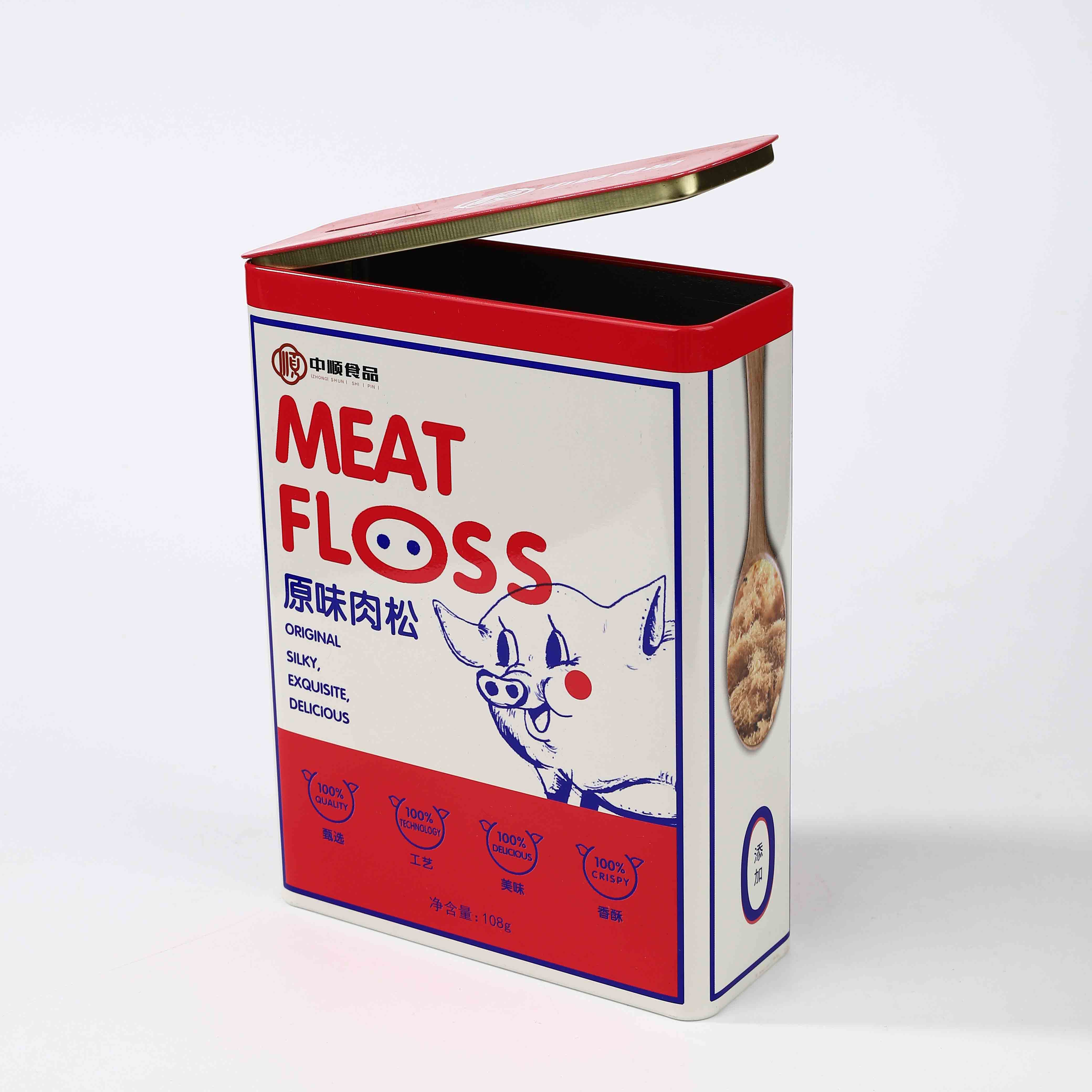

In the contemporary packaging industry, tin cans have become a ubiquitous choice for a myriad of food and beverage products. The significance of tin cans extends beyond their practical utility; they are also integral to brand identity and consumer trust. As a result, understanding the pricing dynamics associated with tin can manufacturing is crucial for businesses aiming to optimize their packaging strategies.

The pricing of tin cans is influenced by several key factors, including raw material costs, manufacturing processes, and market demand. Tinplate, the primary raw material used in the production of tin cans, is derived from wrought iron or steel sheets coated with tin. Fluctuations in the prices of these metals directly impact the overall cost of manufacturing tin cans. For instance, when global steel prices surge due to economic factors or geopolitical tensions, cost structures for manufacturers can shift dramatically, leading to increased prices passed on to consumers.

Moreover, the manufacturing processes employed by tin can manufacturers are another crucial determinant of price. Factors such as production capacity, technology used, and operational efficiency all contribute to the cost structure. Advanced manufacturing techniques that reduce waste and enhance productivity often result in lower prices for end consumers. On the flip side, manufacturers that rely on outdated practices may face higher operational costs, ultimately raising the price of their products.

Additionally, market demand plays a pivotal role in shaping tin can prices. The increasing preference for environmentally friendly packaging has spurred demand for tin cans as they are 100% recyclable and often made from recycled materials. This growing demand not only influences pricing strategies but also drives manufacturers to innovate and invest in sustainable practices, which can either increase or decrease prices depending on the investment required.

tin can manufacturers pricelist

Price lists from tin can manufacturers can vary significantly based on order quantities, customization options, and additional services such as printing or labeling. Smaller orders may attract higher per-unit costs compared to bulk purchases, where economies of scale can be realized. Furthermore, custom designs or specialized cans, such as those with unique shapes or features, tend to carry a premium price tag. Therefore, businesses must strategically evaluate their needs to ensure that they are making cost-effective decisions.

Seasonal trends can also impact pricing. For instance, during peak production seasons, such as before the holidays, manufacturers may adjust prices due to heightened demand. Conversely, during off-peak seasons, they might offer discounts to maintain steady production levels.

Lastly, it’s essential for businesses to keep an eye on competitor pricing and market trends. By regularly reviewing price lists from various manufacturers, companies can better position themselves in the marketplace. This practice not only aids in cost management but also enhances negotiation leverage when seeking partnerships with suppliers.

In conclusion, the pricing of tin cans is a complex interplay of raw material costs, manufacturing efficiency, market demand, order specifics, and seasonal trends. For businesses involved in packaging, a thorough understanding of these factors is vital in order to make informed decisions that align with their strategic goals. By continually analyzing the pricing landscape, companies can secure the best possible deals, ensuring their products are both competitively priced and of high quality.

-

Custom Large Metal Box Manufacturers & Suppliers | Durable Solutions

NewsAug.22,2025

-

Top Steel Pail with Lid Manufacturers - Durable & Secure

NewsAug.19,2025

-

Large Metal Box Manufacturers: Custom & Durable Solutions

NewsAug.18,2025

-

Durable Large Metal Box Manufacturers & Custom Solutions

NewsAug.17,2025

-

Large Metal Box Manufacturers | Durable & Custom Solutions

NewsAug.16,2025

-

Top Steel Pail with Lid Manufacturers | Durable & Secure Solutions

NewsAug.15,2025