Aug . 28, 2024 06:02 Back to list

Tin Manufacturers USA - High-Quality Tin Products & Solutions

Exploring Tin Manufacturers in the USA A Comprehensive Overview

Tin, a versatile and essential metal, has long been utilized in various industries ranging from food packaging to electronics. With its unique properties such as corrosion resistance, malleability, and conductivity, tin plays a crucial role in many applications. In the United States, several manufacturers specialize in producing tin products, catering to both domestic and international markets.

One of the leading tin manufacturers in the USA is Pennsylvania-based T.B. Penick & Sons, a company that has been operating for over a century. Known for its high-quality tin products, T.B. Penick & Sons has established itself as a reliable supplier for various sectors, including construction and artisanal crafts. Their dedication to sustainability means they also focus on recycling and reusing tin, contributing to environmental conservation efforts.

Exploring Tin Manufacturers in the USA A Comprehensive Overview

Berg Steel Pipe Corp, while primarily known for its steel products, also has a division dedicated to manufacturing tin-coated products. Their innovative approach integrates advanced manufacturing technologies, ensuring that the tin products produced meet the highest industry standards. Berg Steel’s commitment to research and development enables them to create new applications for tin, pushing the boundaries of what can be achieved with this remarkable metal.

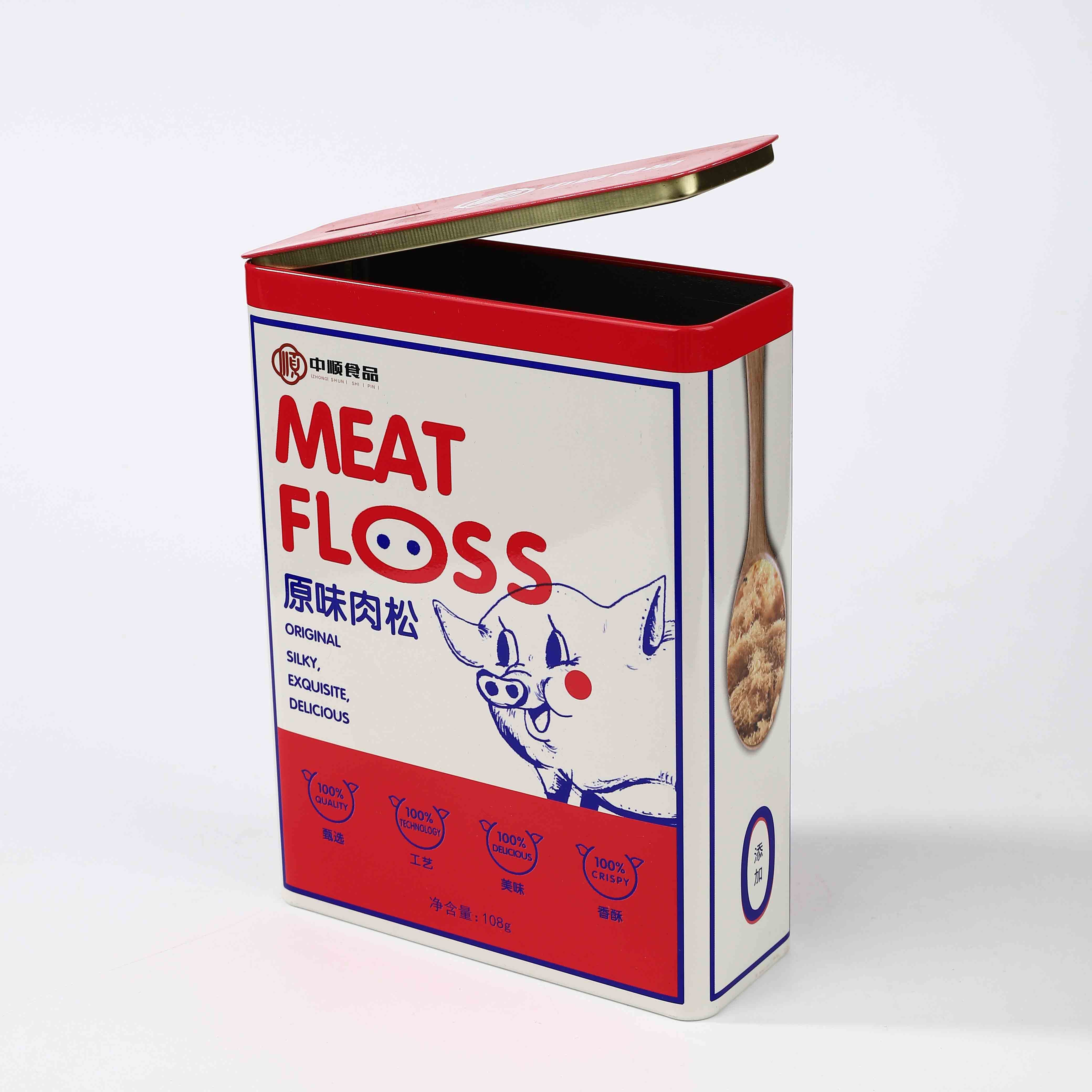

tin manufacturers usa product

In addition to these major manufacturers, numerous smaller companies and local artisans produce handcrafted tin products. For example, Tin Man's Parlor, located in Oregon, specializes in custom-made tin fixtures and home décor items. Their products, which range from decorative tiles to unique lighting fixtures, showcase the artistic potential of tin and highlight the creative spirit of local artisans.

The U.S. tin manufacturing industry faces ongoing challenges, including fluctuating raw material prices and competition from international markets. Despite these obstacles, many manufacturers are adapting by focusing on innovation and sustainability. Advanced manufacturing techniques, such as additive manufacturing and recycling processes, are being employed to optimize production and reduce waste.

The demand for tin is not only sustained by traditional industries but is also growing in new sectors such as electronics and renewable energy. As the world shifts towards greener technologies, the role of tin in components like solder and batteries becomes increasingly vital. This trend provides an opportunity for U.S. manufacturers to expand their product lines and invest in research to develop advanced materials.

To conclude, the tin manufacturing landscape in the United States is marked by a blend of established companies and emerging players, each contributing to the metal’s multifaceted applications. As the industry evolves, it holds promise for innovation and sustainability, ensuring that tin remains a staple material in various sectors for years to come. Whether through large-scale production or artisanal craftsmanship, the commitment to quality and creativity continues to drive tin manufacturers in the USA forward.

-

High-Quality Round Aluminum Box Custom Sizes & Wholesale Prices

NewsJul.08,2025

-

Premium Spice Box – High-Quality Spice Box Product from Leading Factories Inspiring Spice Box Quotes

NewsJul.08,2025

-

Premium Chocolate Oral Box for Gifts & Events Chocolate Oral Box Product Quotes & Factories

NewsJul.08,2025

-

Premium Round Biscuit Tin Box – Custom Product, Quotes & Factory Direct Supply

NewsJul.07,2025

-

Car Box Durable Storage Solutions for Vehicles Reliable Car Box Product Quotes from Leading Factories

NewsJul.07,2025

-

5 Gallon Metal Bucket with Lid Suppliers & Exporters – Durable & Secure Storage Solutions

NewsJul.07,2025