Oct . 30, 2024 15:11 Back to list

standard tin size manufacturer

The Importance of Standard Tin Size Manufacturers

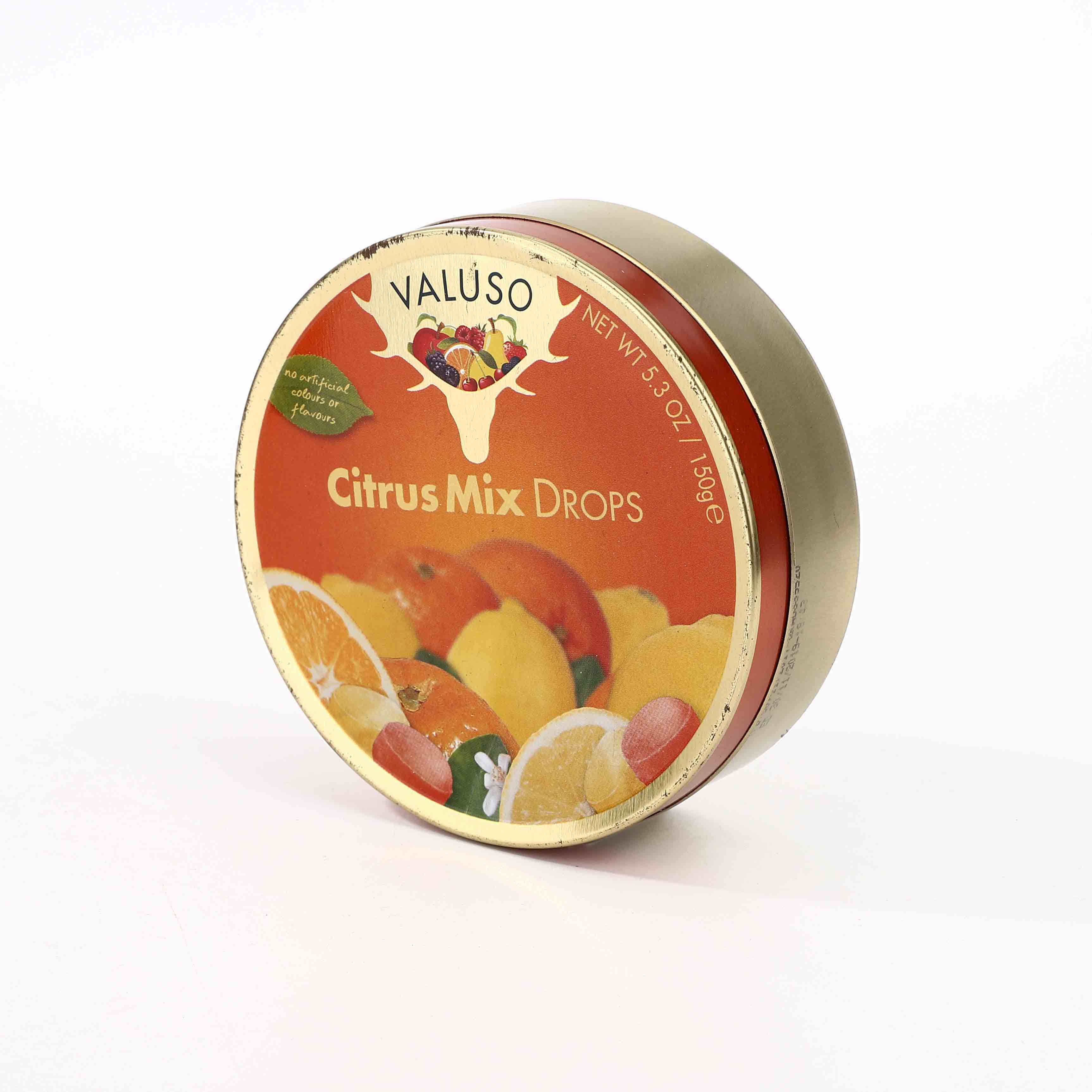

In today’s manufacturing landscape, standard tin sizes play a critical role, especially in the packaging and food preservation industries. Tin, often used for its excellent malleability and resistance to corrosion, is a popular choice for packaging various products, from food to chemicals. Among various tin products, standard tin sizes ensure consistency, quality, and compatibility across different applications.

Standard tin size manufacturers are essential players in this sector, providing products that meet specific industry requirements. These manufacturers adhere to established dimensions that ensure products fit seamlessly into existing systems, reducing waste and optimizing production efficiency. For example, in the food industry, where canned goods are ubiquitous, a standardized tin size allows for automated filling, labeling, and shipping processes. This standardization not only streamlines operations for manufacturers but also benefits retailers and consumers by ensuring uniformity in product offerings.

One of the key advantages of working with standard tin size manufacturers is the ability to maintain cost-effectiveness. When manufacturers produce tins in standardized sizes, they can achieve economies of scale, reducing the cost of production. This cost-saving can be passed down the supply chain, resulting in less expensive products for consumers. Additionally, standardized sizes facilitate easier inventory management, as suppliers can stock a set range of tin sizes that meet a broad array of customer needs.

standard tin size manufacturer

Moreover, environmental considerations are increasingly significant in manufacturing processes today. Standard tin sizes can contribute to sustainability initiatives by minimizing material waste. When production processes utilize uniform dimensions, cutting and shaping materials become more efficient. As a result, less off-cut waste is generated, thereby promoting a more eco-friendly manufacturing approach.

It's also worth noting the importance of regulatory compliance in the industry. Standard tin size manufacturers often adhere to stringent guidelines regarding safety and quality. By following standardized specifications, these manufacturers help ensure that their products are safe for use, particularly in food-related applications. This compliance fosters trust among consumers, who increasingly seek transparency and assurance regarding the products they purchase.

In conclusion, standard tin size manufacturers play a vital role in various industries, particularly in packaging. By delivering consistent, cost-effective products, they enhance operational efficiency while adhering to environmental and regulatory standards. As the demand for quality packaging solutions continues to grow, the significance of these manufacturers will only increase. Embracing standardization in tin sizes not only benefits the production process but also sustains trust with consumers in an ever-evolving marketplace.

-

Durable Large Metal Boxes | Top Manufacturers & Suppliers

NewsAug.09,2025

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025

-

Leading Large Metal Box Manufacturers | Custom Solutions

NewsAug.04,2025