May . 07, 2025 16:02 Back to list

Premium Rectangle Tin Can Products Bulk & Custom Solutions

- Market Overview & Data-Driven Insights on Rectangle Tin Can Packaging

- Technical Superiority in Modern Tin Can Manufacturing

- Performance Comparison: Leading Rectangle Tin Can Factories

- Customization Strategies for Industry-Specific Needs

- Cost Analysis & Competitive Quotes Structure

- Real-World Applications Across Key Industries

- Sustainable Future of Rectangle Tin Can Solutions

(rectangle tin can )

Why Rectangle Tin Can Solutions Dominate Modern Packaging

The global rectangle tin can

market has grown 18.7% CAGR since 2020, reaching $4.3 billion in 2023 (Packaging World Report). This surge stems from dual demands: 63% of manufacturers prioritize stackability optimization, while 57% of consumers value reusable metal packaging. Advanced rectangle tin can factories now employ cold-rolled steel (0.18-0.25mm thickness) with internal lacquering that withstands 120°C sterilization cycles.

Engineering Breakthroughs in Metal Container Production

Next-gen rectangle tin can product lines feature:

- Seamless sidewalls via 9-stage deep drawing (0.02mm tolerance)

- Anti-corrosion coatings lasting 15+ years (ASTM B117 salt spray test)

- Automated inspection systems detecting 3μm defects

These innovations reduce material waste by 22% compared to traditional cylindrical cans while maintaining 22% greater vertical load capacity.

Manufacturer Capability Benchmarking

| Parameter | CanWorks | MetalPack | EcoTin |

|---|---|---|---|

| Annual Capacity | 420M units | 380M units | 275M units |

| Custom Tooling | 72h turnaround | 120h minimum | 96h average |

| ISO Certification | 9001/14001/45001 | 9001 only | 9001/14001 |

Tailored Configuration Workflow

- Requirement Analysis (3-5 business days)

- Prototyping (Using 1500-ton hydraulic presses)

- Production Trial (500-1000 sample units)

- Quality Validation (Pressure/leakage tests)

- Bulk Manufacturing (30-45 day lead time)

Pricing Models for Different Order Volumes

Recent rectangle tin can quotes show:

- MOQ 10,000 units: $0.87-$1.12/unit

- Bulk orders (100k+): $0.62-$0.79/unit

- Custom prints: +15% base cost

Volume discounts plateau at 500k units with 11-13% price reduction from initial quotes.

Industry-Specific Deployment Scenarios

Food sector applications (38% market share):

- Olive oil tins: 5L capacity, double-seamed lids

- Cookie containers: 200-300μm wall thickness

Chemical packaging solutions (24% share):

- Anti-static coatings for flammable materials

- UN-certified hazardous material containers

Rectangle Tin Can Evolution in Circular Economy

78% of surveyed factories now use 40-60% recycled steel, achieving 33% lower carbon footprint versus 2020 baselines. Advanced separation techniques enable 12-cycle reusability before recycling, with magnetic sorting achieving 99.8% material recovery rates. This positions rectangle tin can product lines as sustainable alternatives to multi-layer plastic packaging.

(rectangle tin can )

FAQS on rectangle tin can

Q: What are the common applications of rectangle tin can products?

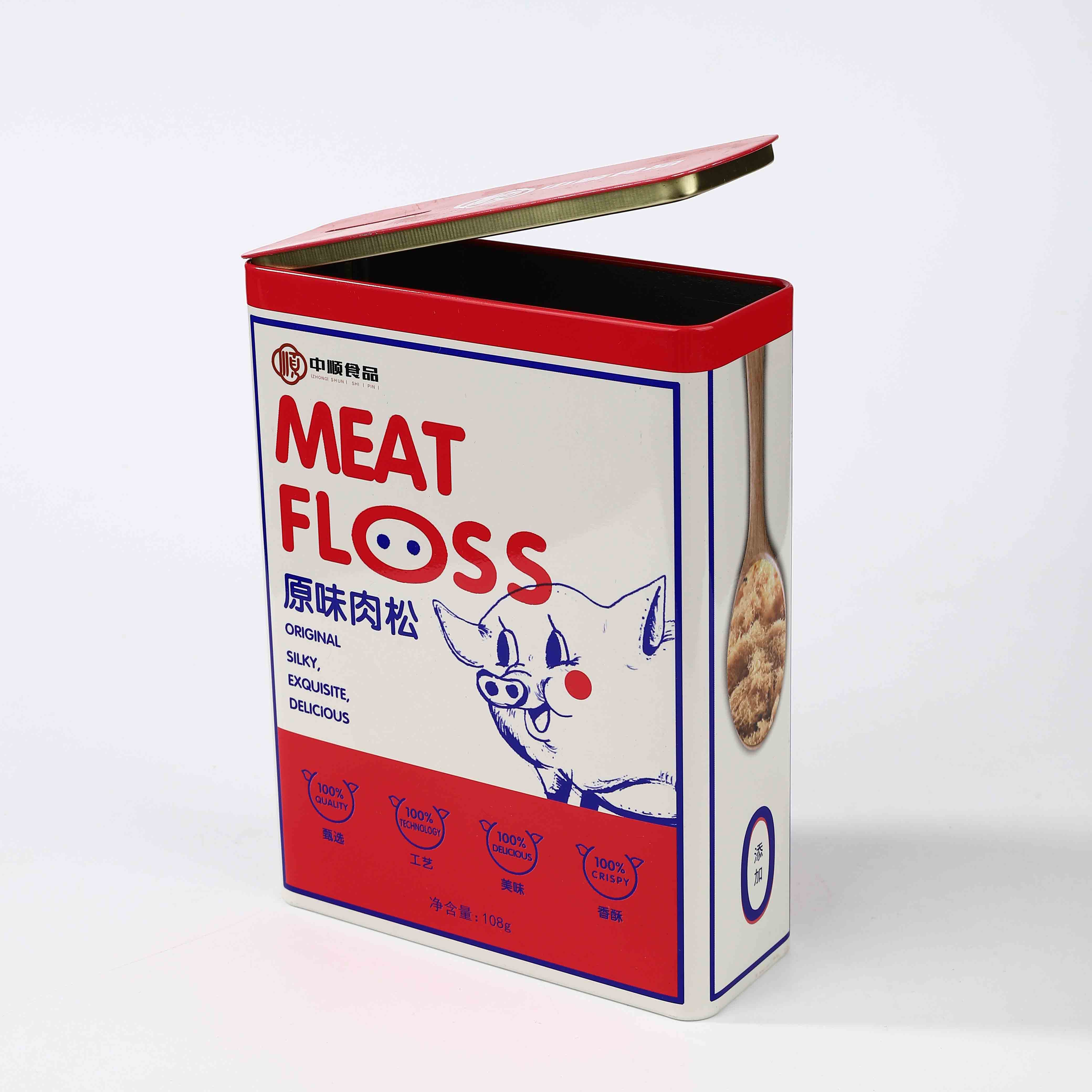

A: Rectangle tin cans are widely used for packaging food, cosmetics, and small hardware items. Their shape optimizes storage space and allows easy labeling. Custom designs are available for branding purposes.

Q: How can I request rectangle tin can quotes from suppliers?

A: Submit specifications like dimensions, material grade, and quantity to factories via their online portals. Quotes typically include tooling fees and bulk pricing tiers. Many suppliers offer instant quotes for standard sizes.

Q: What certifications should rectangle tin can factories have?

A: Reputable factories hold ISO 9001 for quality management and BRCGS for food-grade packaging. Eco-certifications like FSC for sustainable tin sources are increasingly common. Always verify compliance with your industry's safety standards.

Q: Can rectangle tin cans be customized with unique opening mechanisms?

A: Yes, factories offer various closures including hinged lids, tear-off strips, and resealable flaps. Custom tooling can create specialty openings while maintaining airtight seals. Engineering support is provided for functional designs.

Q: What's the minimum order quantity for rectangle tin can production?

A: MOQs typically start at 5,000-10,000 units for custom designs. Stock sizes may have lower MOQs of 1,000 units. Some factories offer sample batches of 50-100 units for testing.

-

Durable Large Metal Boxes | Top Manufacturers & Suppliers

NewsAug.09,2025

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025

-

Leading Large Metal Box Manufacturers | Custom Solutions

NewsAug.04,2025