Dec . 12, 2024 18:10 Back to list

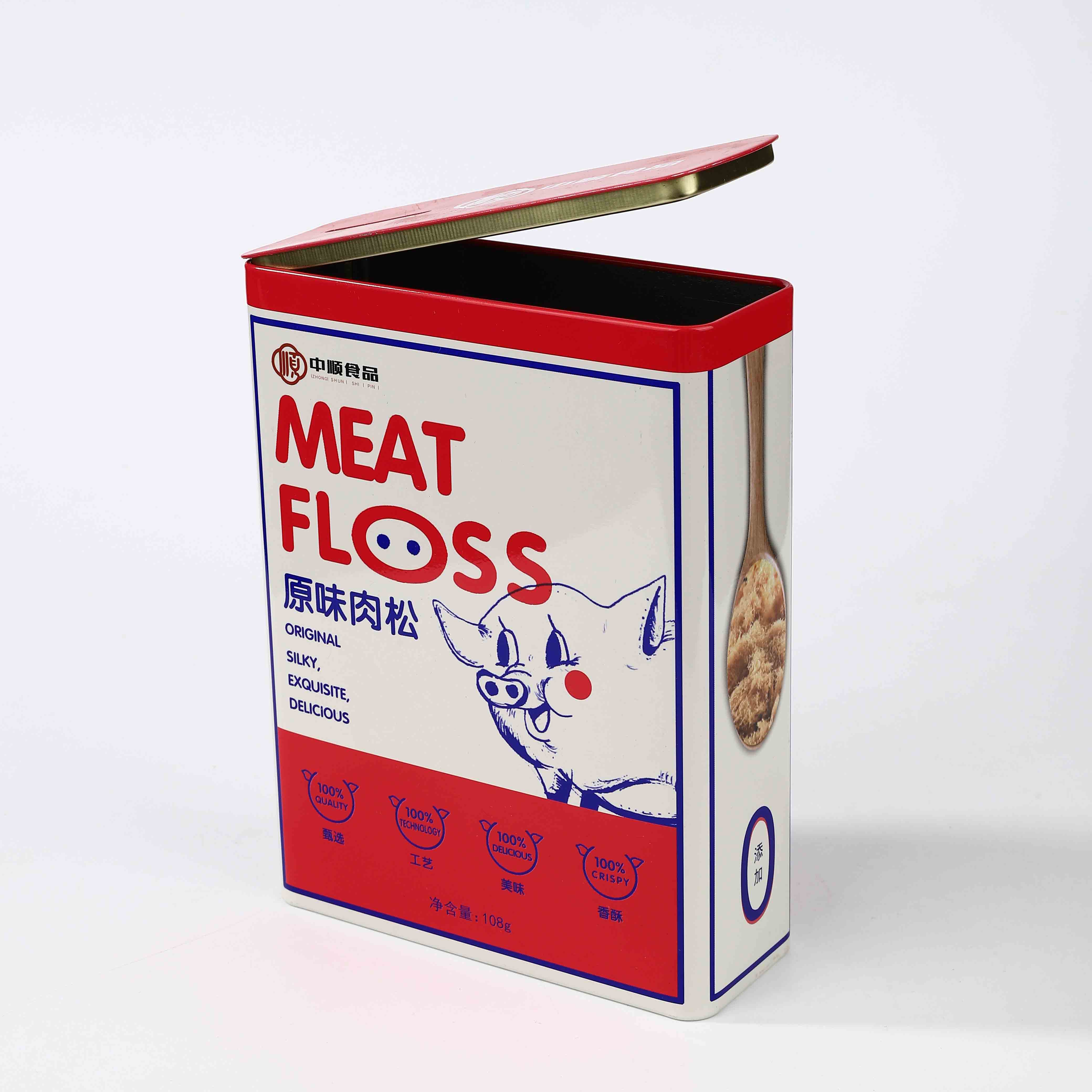

metal cookie tin factory

The Art of Crafting Metal Cookie Tin A Glimpse into the Factory

In the heart of a bustling city, where the aroma of freshly baked cookies wafts through the air, lies a unique factory dedicated to one of the most charming elements of cookie culture the metal cookie tin. This factory stands as a testament to craftsmanship, creativity, and tradition, offering visitors a fascinating insight into the production of these beloved storage containers. The process of creating metal cookie tins is not just about functional design; it’s an art that blends innovation with a rich history.

The Historical Charm of Cookie Tins

Metal cookie tins have been around for over a century, playing a significant role in cookie packaging and preservation. Originating in the late 19th century, these tins were designed not only to keep cookies fresh but also to serve as decorative items that families cherished. Early tins featured intricate designs and artwork, often depicting seasonal scenes or popular motifs of the time. This tradition continues today, as many factories still employ skilled artists to create stunning visuals that grace their products.

The Journey of Production

A typical day in a metal cookie tin factory begins with the selection of high-quality materials. Steel sheets, often coated with a layer of tin to prevent rusting, are the primary raw material used in production. The sheets are sourced from reputable suppliers, ensuring durability and a long life for the finished product.

Once the materials arrive, the first step involves cutting the steel sheets into specific shapes. This is done using advanced machinery that accurately cuts the metal into circular or rectangular forms, depending on the design of the cookie tin. Precision is crucial at this stage, as even the slightest error can affect the final product.

After cutting, the edges of the metal pieces are smoothed out to eliminate any sharp points, ensuring safety for consumers. Following this, the pieces undergo a process called forming, where the flat metal is shaped into the desired structure using hydraulic presses. This machinery can delicately bend the metal into curves or fold it into shapes with remarkable accuracy.

Painting and Decoration

metal cookie tin factory

Once the basic shape of the cookie tin is crafted, the next phase involves decorating it. This is perhaps one of the most enjoyable parts of the production process. The factory employs skilled artists who hand-paint or print designs onto the tins. These designs can range from whimsical illustrations of cookies and cakes to elegant floral patterns, showcasing the versatility and artistic potential of the metal surface.

In addition to hand-painting, modern factories also utilize advanced printing technologies, including digital printing, to achieve vibrant colors and intricate details. This combination of traditional artistry and modern techniques ensures that each cookie tin is not only functional but also a piece of art in its own right.

Quality Control and Assembly

Quality control is a top priority in the metal cookie tin factory. After the tins are decorated, they undergo rigorous inspection to check for any defects or inconsistencies in design. Tins that pass inspection are then assembled, with lids being fitted securely to ensure that they remain airtight.

Once assembled, the tins are packaged and prepared for shipping. The factory often collaborates with various brands and bakeries to provide customized cookie tins for special occasions, holidays, or promotional events, further adding to the charm and appeal of their products.

Embracing Tradition and Innovation

As we step back and admire the final product—the beautifully crafted metal cookie tin—it becomes clear that the factory is not just manufacturing a simple container. It is preserving a tradition that brings joy and nostalgia to countless households. Every cookie tin tells a story, encapsulating memories of homemade treats and family gatherings.

With the push towards sustainable practices, many factories are now exploring eco-friendly materials and production methods, ensuring that the future of metal cookie tins aligns with modern values. This commitment to innovation, coupled with a respect for tradition, ensures that the cookie tin will continue to be a beloved staple in kitchens around the world.

In conclusion, the metal cookie tin factory is a remarkable blend of history, craftsmanship, and modern innovation. It serves as a reminder of the simple joys that come from baking and sharing treats, encapsulated beautifully in a tin that is much more than just a storage solution.

-

Durable Large Metal Boxes | Top Manufacturers & Suppliers

NewsAug.09,2025

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025

-

Leading Large Metal Box Manufacturers | Custom Solutions

NewsAug.04,2025