Dec . 23, 2024 16:47 Back to list

lids for tin cans companies

The Importance of High-Quality Lids for Tin Cans A Growing Industry

In recent years, the global demand for tin cans has surged, driven by the expansion of the food and beverage industry, as well as an increasing preference for sustainable packaging options. One crucial component of tin cans that often goes unnoticed is the lid. While the can itself may garner a lot of attention, the lid plays an essential role in ensuring the freshness, safety, and longevity of the products contained within. This article explores the significance of high-quality lids for tin cans and highlights the companies leading the way in this burgeoning industry.

The Role of Lids in Food Safety and Quality

Lids for tin cans serve several critical functions. Firstly, they provide an airtight seal that protects the contents from contaminants, bacteria, and external elements. This is especially vital for perishable goods such as fruits, vegetables, and dairy products, which can spoil quickly if not adequately sealed. Moreover, the integrity of the lid influences the shelf life of canned goods. An effective seal prevents air from entering and ensures that oxidation does not compromise the flavor and nutritional value of the food.

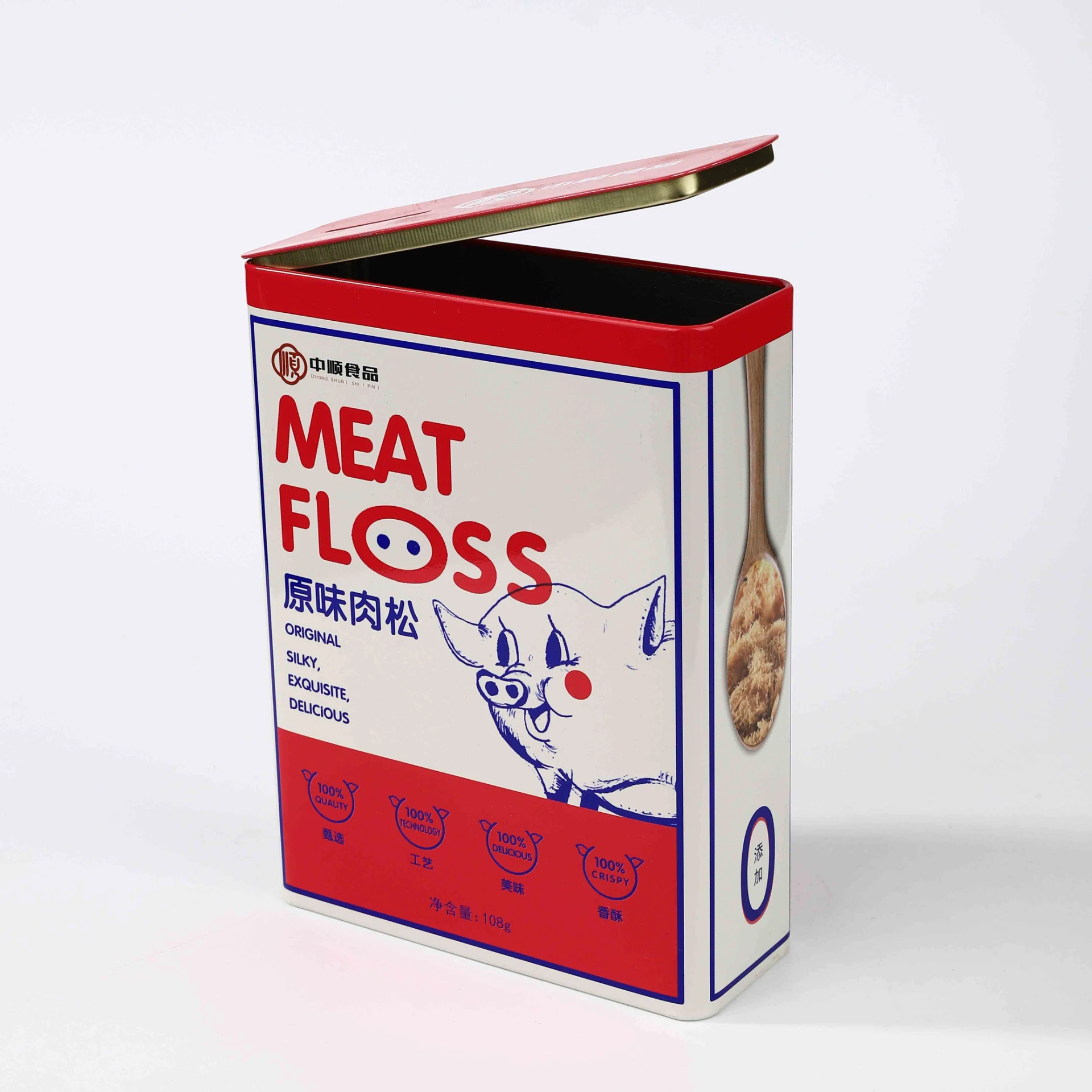

Secondly, lids are crucial in maintaining the aesthetic appeal of products. Contemporary consumers are increasingly discerning; they expect packaging to be visually appealing while also being functional. Companies that prioritize high-quality lid design often engage in creative branding opportunities, utilizing colors, logos, and shapes that resonate with their target audience.

Innovations in Lid Manufacturing

Several companies are at the forefront of producing tin can lids that combine functionality and design. These companies invest heavily in research and development to create innovative solutions that enhance the performance of their lids. For example, many manufacturers focus on creating easy-to-open lids that reduce the struggle often associated with traditional canning technology. This is particularly beneficial for older adults and individuals with limited dexterity.

Additionally, advancements in materials technology have led to the development of more robust and environmentally friendly lid options. Many leading companies are now using recyclable and biodegradable materials in their lid designs, aligning with global sustainability goals. This shift not only addresses consumer concerns about plastic waste but also positions brands as environmentally responsible, enhancing their market appeal.

lids for tin cans companies

Leading Companies in the Lids for Tin Cans Market

Several companies are recognized for their excellence in producing tin can lids. Ball Corporation is one of the largest manufacturers worldwide, renowned for its quality and innovation. They produce a variety of food and beverage containers, including an impressive range of lids that cater to different market needs.

Another notable player is Crown Holdings, which has made significant strides in developing easy-open and re-closable lid options, enhancing user convenience. Their commitment to sustainability is evident in their initiatives to decrease the carbon footprint associated with their production processes.

Silgan Holdings is also a key industry player, focusing on delivering high-performance lids designed to prevent contamination while using materials that meet modern ecological standards. Their R&D efforts have led to breakthroughs in seal technology that improve shelf-life and food safety.

Conclusion

The market for high-quality lids for tin cans is becoming increasingly important as consumers demand safe, fresh, and aesthetically pleasing products. The transition towards sustainable packaging solutions further underscores the need for innovation in this segment. Companies like Ball Corporation, Crown Holdings, and Silgan Holdings are pioneering efforts to ensure that the lids of tin cans not only fulfill their practical requirements but also contribute to branding and environmental initiatives.

As the industry continues to evolve, it will be crucial for companies to stay ahead of the curve by embracing new technologies and materials. Ultimately, the success of tin can products will increasingly depend on the quality and functionality of their lids, making it a significant focus for manufacturers worldwide.

-

Leading Large Metal Box Manufacturers & Suppliers - Custom Designs

NewsAug.10,2025

-

Durable Large Metal Boxes | Top Manufacturers & Suppliers

NewsAug.09,2025

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025