Oct . 18, 2024 18:05 Back to list

Flat Tin Production Company for High-Quality Metal Solutions and Custom Fabrication

The Rise of Flat Tin Manufacturing Trends and Innovations

In recent years, the flat tin manufacturing industry has experienced notable growth due to increasing demand in various sectors, including aerospace, automotive, electronics, and packaging. As a key player in the metal manufacturing industry, flat tin manufacturers are adapting to changing market dynamics, advancing their production techniques, and focusing on sustainability.

Flat tin, derived from tin ores, is a versatile material known for its corrosion resistance, malleability, and excellent solderability. These properties make it an ideal choice for a plethora of applications, from food packaging that ensures product freshness to electrical contacts that require reliable performance under tough conditions. The global flat tin market is currently witnessing a shift towards high-quality products that not only meet industrial standards but also cater to consumer preferences for eco-friendly options.

One of the leading trends in flat tin manufacturing is the emphasis on technological advancement. Manufacturers are increasingly investing in state-of-the-art equipment and machinery to enhance the efficiency and precision of their production processes. Innovations such as automated production lines, advanced robotics, and AI-driven analytics are being implemented to optimize operational workflows, reduce waste, and improve product consistency. By harnessing these technologies, manufacturers can respond swiftly to changing market demands and deliver superior products more efficiently.

Moreover, the flat tin industry is embracing digital transformation. With the rise of Industry 4.0, manufacturers are utilizing data analytics and IoT (Internet of Things) devices to monitor production metrics in real-time. This transition not only facilitates predictive maintenance but also allows manufacturers to analyze consumer behavior, tailor their offerings, and drive more informed decision-making. As a result, companies can achieve higher levels of productivity while minimizing costs and resource consumption.

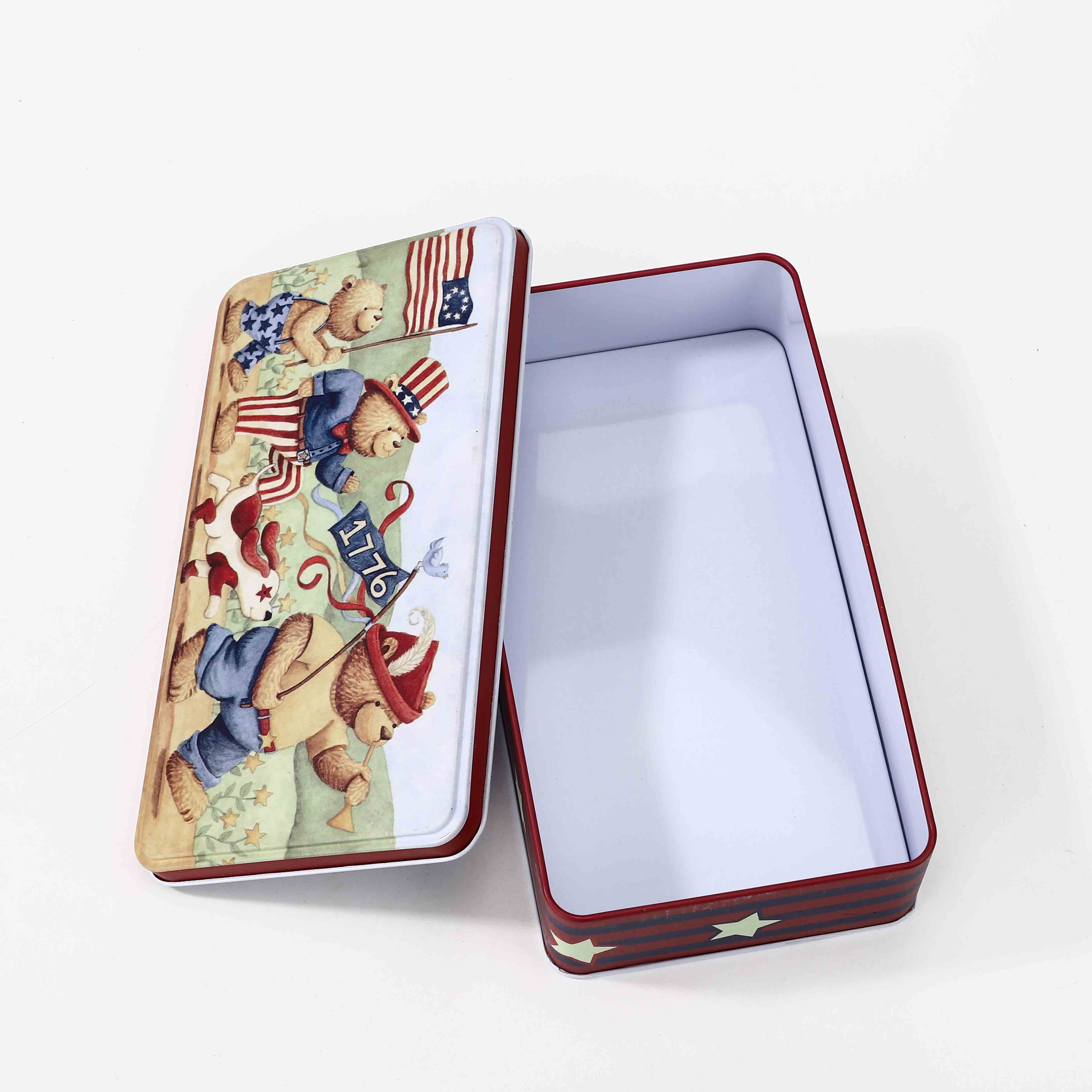

flat tin manufacturer

Sustainability is another pivotal area of focus for flat tin manufacturers. As global awareness of environmental issues increases, consumers and regulatory bodies are demanding more sustainable practices. Many manufacturers are responding by adopting eco-friendly production methods, including recycling initiatives and the use of renewable energy sources. Additionally, there is a concerted effort to source tin responsibly, ensuring that the raw materials come from sustainable and ethical sources. This commitment to sustainability not only aids in meeting regulatory requirements but also enhances brand reputation and customer loyalty.

Moreover, customization has become an important aspect of flat tin manufacturing. With clients seeking specific dimensions, finishes, and coatings tailored to their applications, manufacturers are capitalizing on their ability to provide bespoke solutions. This flexibility enables businesses to cater to niche markets while expanding their product offerings. The ability to produce small batch sizes without compromising on quality has made flat tin manufacturers more competitive, attracting clients from an array of industries.

The global market for flat tin is also benefitting from strategic partnerships and collaborations. Manufacturers are increasingly forming alliances with other companies in the supply chain to enhance their technological capabilities, share knowledge, and expand their market reach. These collaborations can lead to joint ventures for research and development or co-marketing initiatives, allowing manufacturers to leverage each other's strengths and create value for customers.

Challenges do remain in the flat tin manufacturing space, such as fluctuating raw material prices and trade policy uncertainties. Manufacturers must navigate these complexities to maintain profitability and competitiveness. However, by staying abreast of market trends, investing in technology, and committing to sustainability, flat tin manufacturers can position themselves for long-term success.

In conclusion, the flat tin manufacturing industry is evolving rapidly, driven by technological innovations, sustainability efforts, and customized solutions. As manufacturers continue to adapt to changing market demands and consumer preferences, they are not only enhancing their operational efficiency but also contributing to a more sustainable future. With these positive trends in motion, the future of flat tin manufacturing looks promising, with ample opportunities for growth and development in the years to come. Through strategic investments and a commitment to excellence, flat tin manufacturers can solidify their position as leaders in this dynamic industry.

-

Leading Large Metal Box Manufacturers & Suppliers - Custom Designs

NewsAug.10,2025

-

Durable Large Metal Boxes | Top Manufacturers & Suppliers

NewsAug.09,2025

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025