Oct . 18, 2024 01:55 Back to list

Chocolate Box Manufacturers for Elegant Rectangle Packaging Solutions

The Sweet Science of Chocolate Rectangle Box Manufacturing

In the world of confectionery, presentation is just as important as flavor. This is especially true when it comes to luxury products such as chocolates. Among various packaging styles, the chocolate rectangle box stands out for its elegance and practicality. The manufacturing of these boxes is a fascinating amalgamation of art, technology, and sustainability.

Understanding the Demand

The global chocolate industry is booming, with a significant rise in demand for premium chocolates. As consumers seek high-quality products often paired with exquisite packaging, the role of the chocolate rectangle box manufacturer has never been more crucial. These boxes not only protect the delicate chocolates but enhance the overall experience through design and sophistication.

Materials Matter

When it comes to manufacturing chocolate rectangle boxes, selecting the right materials is essential. Most manufacturers gravitate towards high-quality cardboard, which ensures durability and creates an excellent surface for printing. Corrugated cardboard is also popular due to its strength, particularly for larger boxes designed to hold multiple items.

In recent years, there has been a push towards eco-friendly materials. Many manufacturers are now opting for recycled cardboard or sustainable sourcing practices to meet the demand for environmentally friendly packaging. The use of biodegradable materials demonstrates a manufacturer’s commitment to sustainability and can be a significant selling point for eco-conscious consumers.

Design and Functionality

The beauty of a chocolate rectangle box lies in its design. Manufacturers employ skilled graphic designers who understand branding and aesthetic appeal. The box design must reflect the brand identity while also appealing to the target audience. Innovative features, such as embossed logos, intricate patterns, or vibrant color schemes, can make a significant difference in a chocolate box's visual appeal.

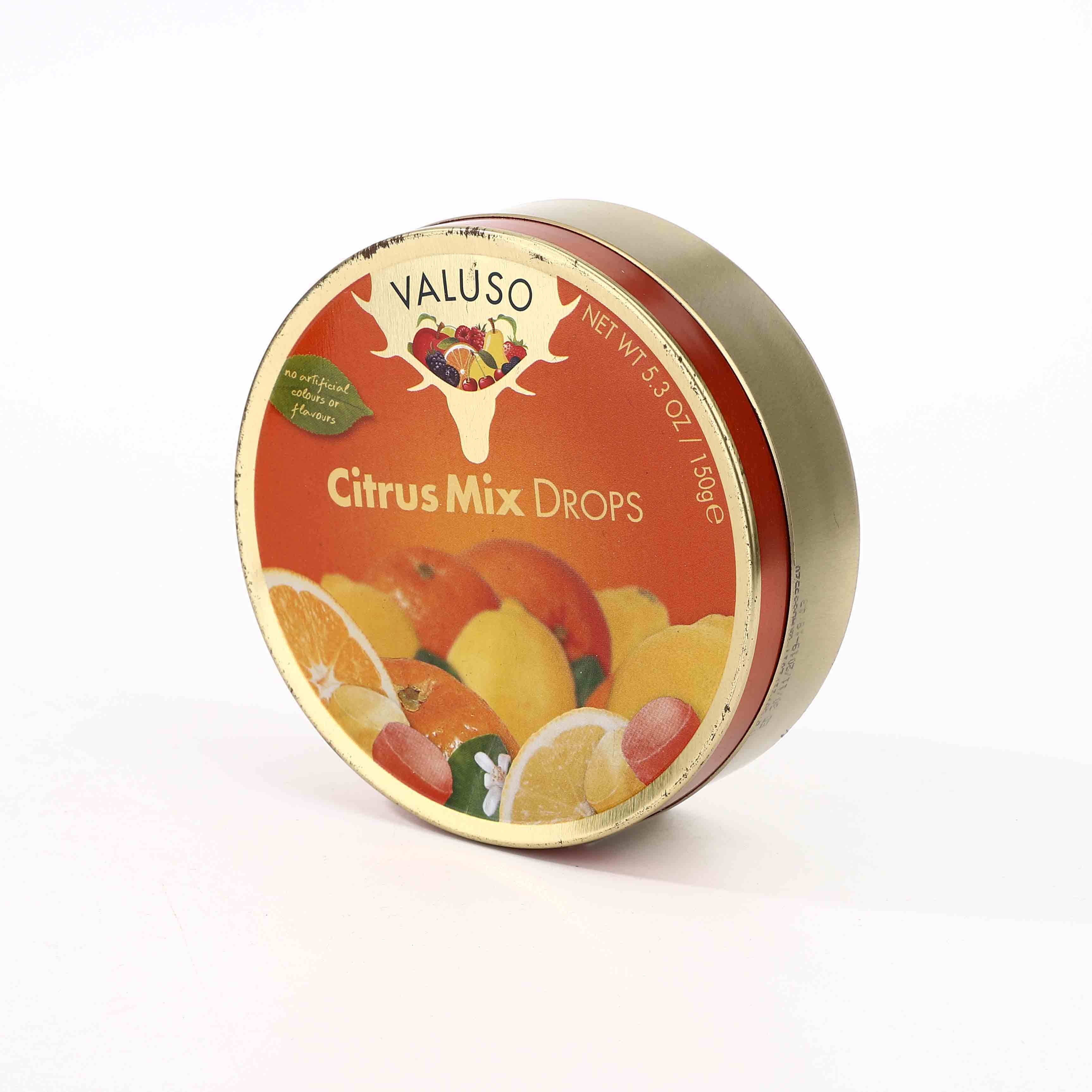

chocolate rectangle box manufacturer

Functionality is equally important. A well-designed box should be user-friendly, allowing consumers to open it with ease while protecting the chocolates inside. Inserts are often used to keep individual pieces in place, preventing them from shifting during transportation. Customization options, such as size, color, and inserts, enable manufacturers to cater to different clientele, from boutique chocolatiers to large-scale distributors.

Manufacturing Process

The process of manufacturing chocolate rectangle boxes involves several steps. It begins with designing the box using specialized software. Once the design is approved, manufacturers create prototypes to ensure the size and design are accurate. Feedback is gathered from clients to make any necessary adjustments.

After finalizing the design, the production phase begins. Large sheets of cardboard are printed, cut, and scored using advanced machinery. Automation plays a significant role in ensuring efficiency and precision, allowing manufacturers to produce high-quality boxes quickly. After assembly, quality control checks are conducted to ensure that each box meets the required standards.

Innovations and Trends

The chocolate packaging industry, like many others, is not immune to trends. Minimalistic design, transparent windows, and multifunctional packaging are gaining popularity. Consumers are increasingly looking for experiences; thus, packaging that tells a story or provides an interactive element, such as QR codes linking to recipes or brand stories, can enhance the consumer experience.

Technology is also making waves in this sector. Manufacturers are exploring smart packaging innovations, which could potentially communicate freshness or authenticity, ensuring that consumers receive the best possible product.

Conclusion

The role of a chocolate rectangle box manufacturer goes beyond merely providing packaging; it encompasses the entire essence of brand identity, consumer experience, and sustainability. With the chocolate industry continuing to thrive, the importance of innovative and functional packaging solutions will only grow. As consumers become more discerning, manufacturers must adapt, blending art with science to create packaging that not only protects but also tantalizes and engages. The humble chocolate rectangle box is not just a means to an end—it’s a crucial element in the journey from the factory to the consumer's palate.

-

Durable Large Metal Boxes | Top Manufacturers & Suppliers

NewsAug.09,2025

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025

-

Leading Large Metal Box Manufacturers | Custom Solutions

NewsAug.04,2025