Nov . 11, 2024 05:10 Back to list

Aluminum and Tin Product Innovations for Modern Manufacturing and Sustainable Solutions

The Significance of Aluminium and Tin Products in Modern Industry

In the contemporary industrial landscape, aluminium and tin products have emerged as pivotal materials that contribute significantly to various sectors, including construction, packaging, transportation, and electronics. Their unique properties and versatility make them indispensable, shaping the way we build, package, and transport goods while promoting sustainability.

The Versatility of Aluminium

Aluminium, a lightweight metal known for its excellent strength-to-weight ratio, plays a crucial role in various applications. Its corrosion resistance, malleability, and ability to conduct electricity make it particularly valuable. In the construction industry, aluminium is used extensively for window frames, roofing, and façade cladding, significantly reducing the weight of structures without compromising durability. Moreover, its reflective qualities allow for energy-efficient buildings, as it can help to regulate indoor temperatures by reflecting sunlight.

In the automotive sector, manufacturers increasingly turn to aluminium to reduce vehicle weight, leading to improved fuel efficiency and lower emissions. For example, vehicles with aluminium components can experience weight reductions of up to 50%, translating into a significant decrease in fuel consumption. This shift not only meets regulatory requirements but also addresses consumer demands for greener vehicles.

The aerospace industry also benefits from aluminium's properties. Aircraft manufactured with aluminium components can achieve higher performance levels, including enhanced speed and fuel efficiency. Thus, aluminium is a critical material that supports innovation and development in technology and design.

Tin and Its Applications

Tin, though less dominant than aluminium, also plays a vital role in various industrial applications. Primarily known for its use in coatings to prevent corrosion, tin is a key component in the production of tinplate, a steel sheet coated with tin. This material is widely used in food packaging, where it plays a crucial role in preserving the quality and safety of food products. Tin's non-toxic properties make it especially suitable for packaging, as it does not affect food taste or quality.

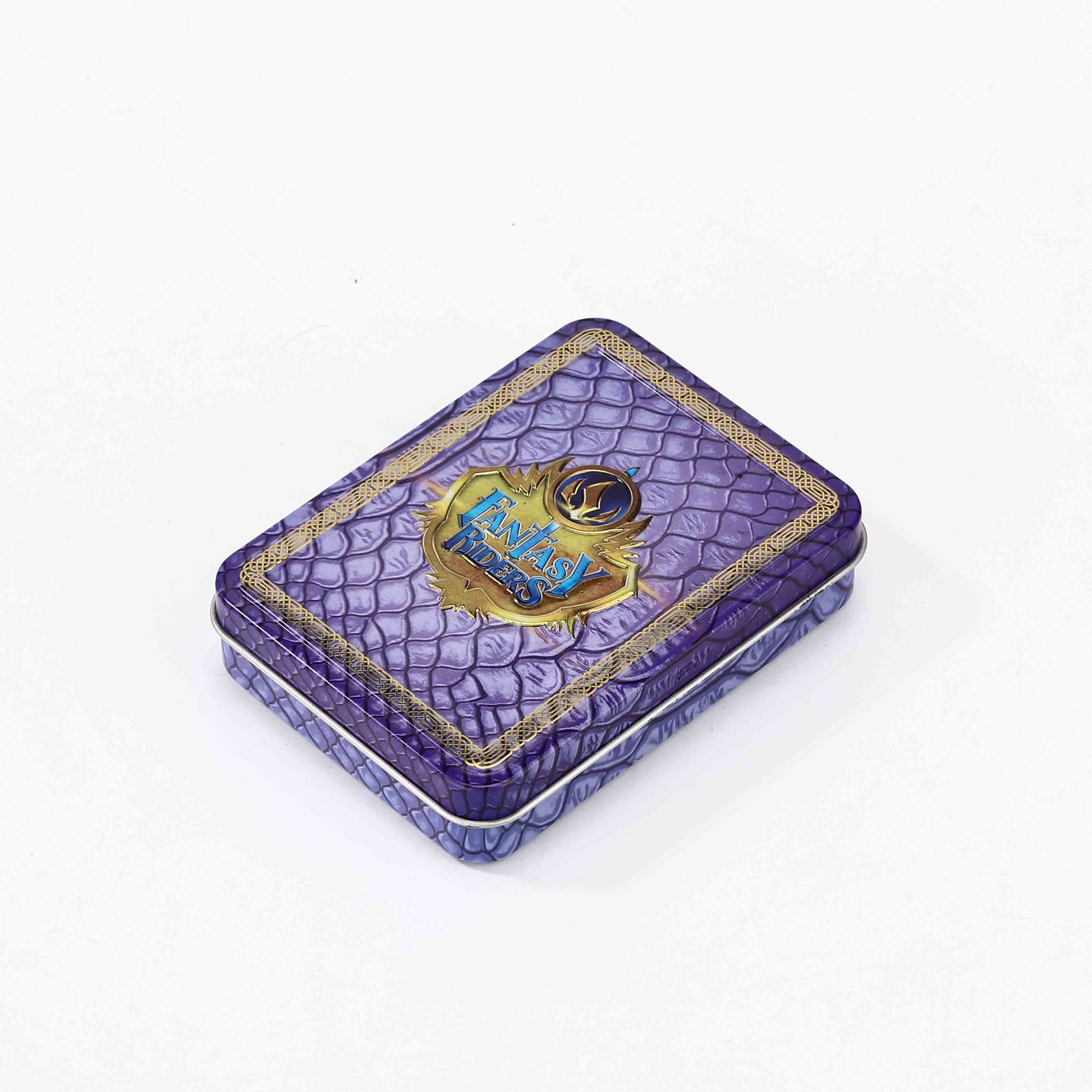

aluminium and tin products

Moreover, tin is essential in soldering, which is a pivotal process in electronics manufacturing. Tin-lead alloys were traditionally preferred, but with environmental concerns over lead toxicity, there has been a significant shift toward lead-free solders. This transition has encouraged the development of new tin-based alloys that meet industry standards while being environmentally friendly.

In addition to its applications in packaging and electronics, tin also finds use in various alloys, including bronze, which is essential in the production of musical instruments, gears, and bearings. These alloys benefit from tin’s corrosion resistance and ability to withstand wear and tear, making them invaluable in many mechanical applications.

Sustainability and Recycling

Both aluminium and tin are highly recyclable materials, which aligns with the modern industry's push towards sustainability. Aluminium recycling is a well-established process that reduces energy consumption significantly. It takes only 5% of the energy required to produce new aluminium from ore, making aluminium one of the most commonly recycled materials in the world. This recycling capability has led to the establishment of a circular economy, where products made from recycled aluminium can be reused infinitely without loss of quality.

Similarly, tin recycling contributes to a reduction in mining and manufacturing impacts on the environment. By recycling tin, manufacturers can minimize waste and conserve natural resources, making it an essential practice in sustainable manufacturing.

Conclusion

In conclusion, aluminium and tin products are vital to modern industry, serving a multitude of applications across various sectors. Their properties, including strength, lightness, corrosion resistance, and recyclability, make them essential materials in promoting sustainability and efficiency. As industries continue to innovate, the importance of aluminium and tin will likely grow, further integrating these materials into future technologies and processes. Understanding their role not only in usability but also in environmental impact management is crucial for businesses aiming to thrive in an increasingly eco-conscious world.

-

Durable Large Metal Boxes | Top Manufacturers & Suppliers

NewsAug.09,2025

-

Custom Large Metal Box Manufacturers: Durable & Reliable Solutions

NewsAug.08,2025

-

Large Metal Box Manufacturers - Custom & Durable Solutions

NewsAug.07,2025

-

Durable Large Metal Box Manufacturers | Custom Solutions

NewsAug.06,2025

-

Large Metal Box Manufacturers | AI-Powered Solutions

NewsAug.05,2025

-

Leading Large Metal Box Manufacturers | Custom Solutions

NewsAug.04,2025