វិច្ឆិកា . 27, 2024 09:47 Back to list

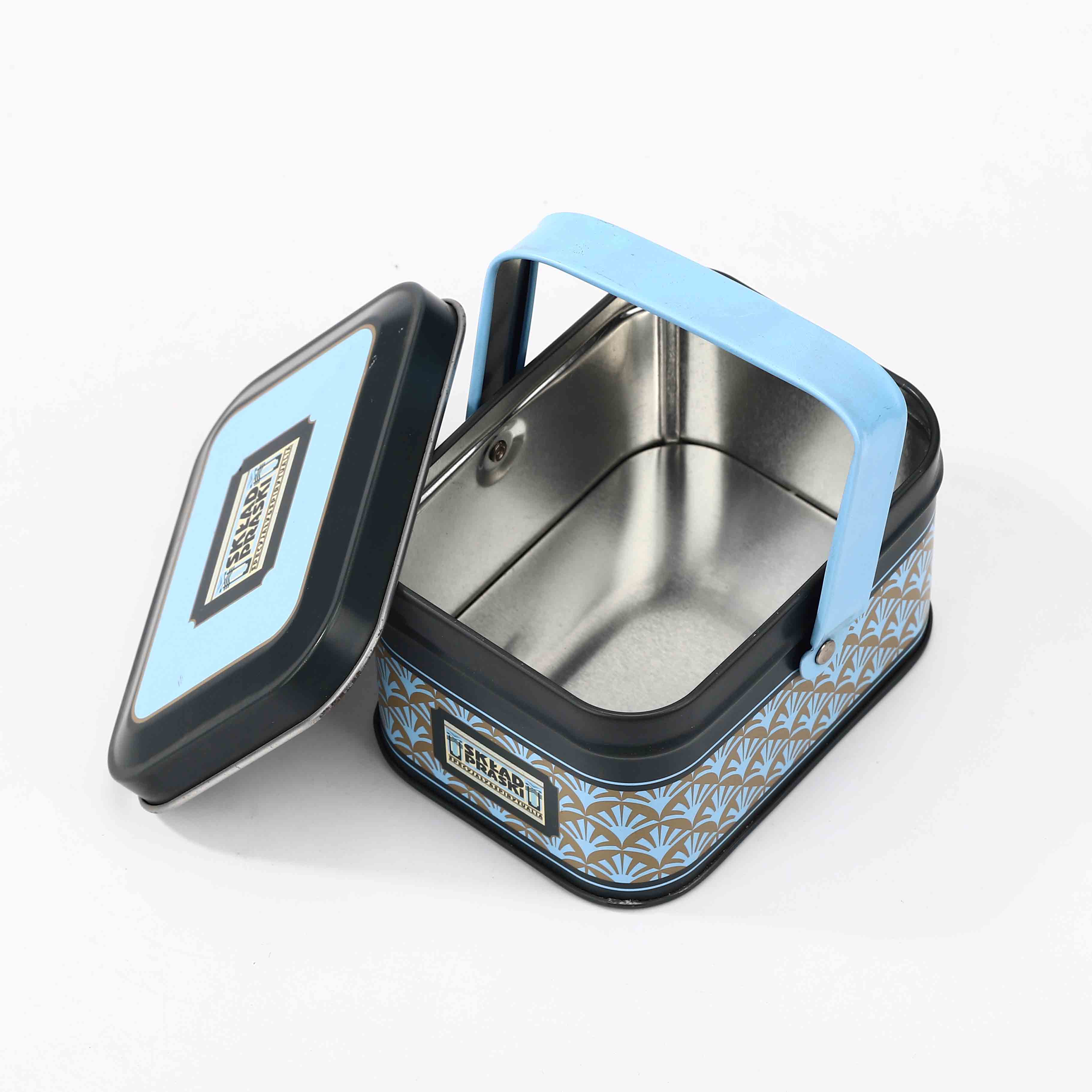

Factory for Manufacturing Square Tin Containers with Quality Assurance and Custom Designs

The Craftsmanship Behind Square Tin Containers A Glimpse into the Factory

In the realm of packaging solutions, square tin containers have gained significant popularity due to their versatility, durability, and aesthetic appeal. These containers are not just functional; they are also an embodiment of craftsmanship and innovation in manufacturing. Behind their shiny exterior lies a fascinating process that combines traditional methods with modern technology in the factory setting.

The journey of a square tin container begins with raw materials, primarily tinplate, which is a thin steel sheet coated with a layer of tin. The choice of tinplate is crucial, as it provides excellent corrosion resistance and a shiny finish. In a typical factory environment, sheets of tinplate are sourced from trusted suppliers to ensure high-quality outputs. Once the materials are ready, the production process commences.

The Craftsmanship Behind Square Tin Containers A Glimpse into the Factory

Once the designs are finalized, the tinplate sheets are cut into the desired shapes. Advanced cutting machines, often automated for efficiency and precision, handle this task. After cutting, the sheets are shaped into their definitive forms using molds and presses. The square shape of these containers requires specialized machinery to ensure that the corners are sharp and the edges are smooth, which is essential for both appearance and safety.

square tin containers factory

After shaping, the containers undergo a critical stage known as coating. In this process, a protective lacquer is applied to the interior and exterior surfaces. The lacquer not only enhances the visual appeal but also provides a barrier against moisture and environmental factors that could affect the contents. Many factories employ eco-friendly coating materials to align with sustainability practices, reflecting the growing consumer demand for environmentally responsible products.

Following the coating phase, the square tin containers are printed with designs and branding. This is another area where technology plays a significant role. Factories often utilize digital printing technology, allowing for high-quality graphics and intricate designs that can be produced in short runs. This capability is particularly beneficial for businesses seeking customized packaging solutions that stand out on the shelves.

Once printed, the containers go through a quality control process where they are inspected for defects such as scratches, dents, or inconsistencies in printing. Quality assurance is paramount in the factory to maintain a high standard of production. Any defective pieces are either repaired or discarded, ensuring that only the best products reach the market.

The final step in the process is packaging and distribution. The square tin containers are sorted, packed, and prepared for shipment to various retailers, wholesalers, or end customers. Factories often work closely with logistics partners to ensure timely delivery, as demand for packaging solutions can be seasonal or fluctuate based on consumer trends.

In conclusion, square tin containers are more than mere packaging; they are a fusion of art and industry. The factory process that brings these containers to life showcases the intricate balance between tradition and technology. With their unique properties and customizable designs, square tin containers continue to be a popular choice across various industries, proving that even the simplest items can have a profound impact on functionality and aesthetics. As the world moves forward, the innovation within the square tin container factory remains a testament to human ingenuity and craftsmanship.

-

Custom Large Metal Box Manufacturers & Suppliers | Durable Solutions

NewsAug.22,2025

-

Top Steel Pail with Lid Manufacturers - Durable & Secure

NewsAug.19,2025

-

Large Metal Box Manufacturers: Custom & Durable Solutions

NewsAug.18,2025

-

Durable Large Metal Box Manufacturers & Custom Solutions

NewsAug.17,2025

-

Large Metal Box Manufacturers | Durable & Custom Solutions

NewsAug.16,2025

-

Top Steel Pail with Lid Manufacturers | Durable & Secure Solutions

NewsAug.15,2025