កុម្ភៈ . 21, 2024 14:52 Back to list

tins-10 Steps Tell You How To Make Tin Box Packaging?

10 Steps Tell You How To Make Tin Box Packaging?

Tinplate, also known as tin-plated iron, is a common name for electroplated tin steel sheets. Tin mainly plays a role in preventing corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability, and beautiful appearance of tin into one material, which has the characteristics of corrosion resistance, non-toxicity, high strength, and good ductility.

Now Let’s learn more about how to do tin packaging production steps:

1. purchasing tinplate

When we got the customer's order, we will arrange to purchase a tinplate first.

2. cutting the tinplate

Since it is manual can make, it is necessary to cut the printing iron of no big than 1060X960mm (the size of the printing machine cylinder) according to the size of the typesetting so that the staff can print the tinplate. This process is completed by the staff operating the shearing machine.

3. printing tinplate

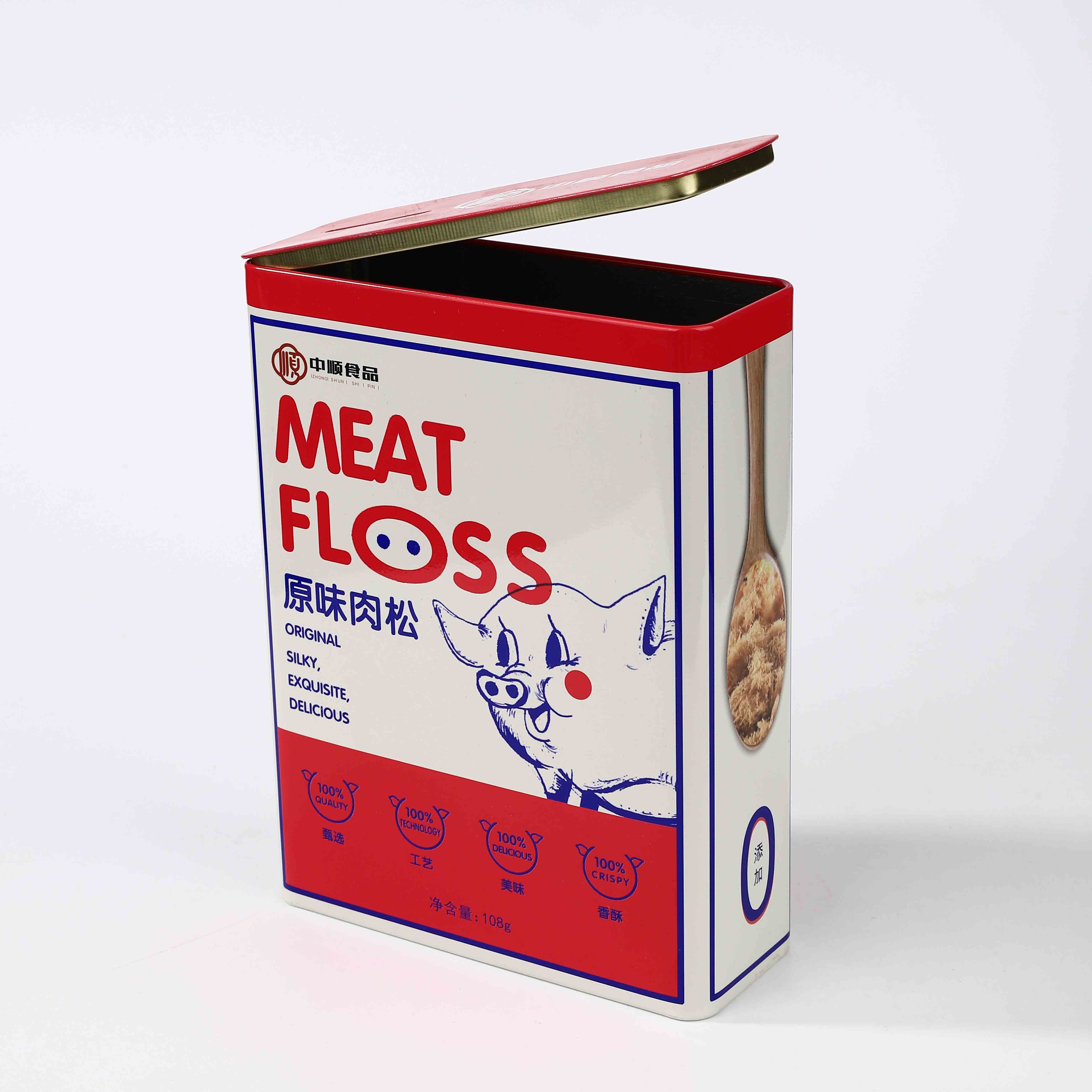

Nowadays, most tin boxes are printed with exquisite patterns, so that the tin boxes not only play the role of food preservation but also have a decorative appearance. The tinplate printing process is completed on the printing iron production line. The printing iron production line is generally composed of equipment such as a feeding device, offset printing unit, coating unit, drying room, and film receiving device.

FOOD TIN BOX RECTANGLE SHAPE HINGE LID

Tinplate printing is transmitted to the surface of the iron sheet by the roller under the appropriate printing pressure through the principle of ink balance.

According to the design effect of the printing pattern, there are two pretreatment methods before tinplate printing: one is over-white coding, and the other is white ink. Over white coding is to apply a layer of tinplate paint called white coding on the tinplate. Printing white ink is to print white ink on the part of the tinplate through the PS version (according to the design document, white ink is printed on the place where the pattern needs to be printed for color printing).

White is the base color of all pictures and has high brightness. After adding other high-energy hues, it can improve the brightness of each hue to form a gradation. However, two different pretreatments of white cotton and white ink will bring different printing effects:

4. cutting tinplate to fit for tin box

5. Punching tin box (lid, body, and bottom)

Tinplate has good ductility and can be stamped into cans of various shapes. A tin box usually consists of a lid and a can body..A tin box, no matter the size, is made by stamping through multiple stamping processes, ranging from eight or nine processes to twenty or thirty processes. The number of processes has nothing to do with the size of the tin box, it mainly depends on the structure and complexity of the tin box. The basic processes of tin box stamping are: can lid (can bottom): cutting material - flashing - winding; can body: cutting angle - Bend over - beat the bones - set the bones - buckle the bottom (gong bottom) - curl edge

6. Clean tin box

The tin box punched in the production workshop will be sent to the packing workshop for cleaning and assembly, and the packaging personnel will use medical alcohol to clean the tin box.

There are many tin boxes that still need to be assembled after stamping and are the finished products that are finally seen on the shelf. In addition to tin boxes with hinged connections, there are double iron wires for round cans, rhinestones on the surface of tin boxes, tying or gluing ribbons on tin boxes, and assembling mirrors, handles, and plastic toys on tin boxes Wait. It should be noted that in order to save labor costs, the process of assembling belts, metal buckles, etc. to the iron box that requires rivets is made by machine stamping in the stamping production workshop.

7. Packing

The metal packaging manufacturer will negotiate with the customer according to the packaging form of the tin box and the type of carton (single pit carton, double pit carton, and three pit carton). After confirming the type of carton and whether the tin box needs to be covered with a protective pp bag or bubble bag before packing, customize the carton. The cleaned and assembled tin box is put into a custom-made carton and sent to for stock warehouse, waiting to be shipped to the customer.

8. Warehousing to warehouse

After packing, send all goods to the warehouse for temporary storage。

9. Transport(by sea, air, or land)

Loading by the container.

10. display to customer supermarket or shop.

-

Large Metal Box Manufacturers: Custom, Durable Industrial Solutions

NewsAug.24,2025

-

Large Metal Box Manufacturers | Custom, Durable & Reliable

NewsAug.23,2025

-

Custom Large Metal Box Manufacturers & Suppliers | Durable Solutions

NewsAug.22,2025

-

Top Steel Pail with Lid Manufacturers - Durable & Secure

NewsAug.19,2025

-

Large Metal Box Manufacturers: Custom & Durable Solutions

NewsAug.18,2025

-

Durable Large Metal Box Manufacturers & Custom Solutions

NewsAug.17,2025