វិច្ឆិកា . 30, 2024 21:29 Back to list

large metal tin supplier

The Role of Large Metal Tin Suppliers in Modern Manufacturing

In today's manufacturing landscape, the demand for high-quality materials is greater than ever. Among these materials, metal tins have carved out a significant niche, being utilized in diverse industries ranging from food packaging to electronics. As a result, large metal tin suppliers play a crucial role in ensuring that manufacturers have access to the resources they need to produce goods efficiently and sustainably.

Understanding Metal Tins

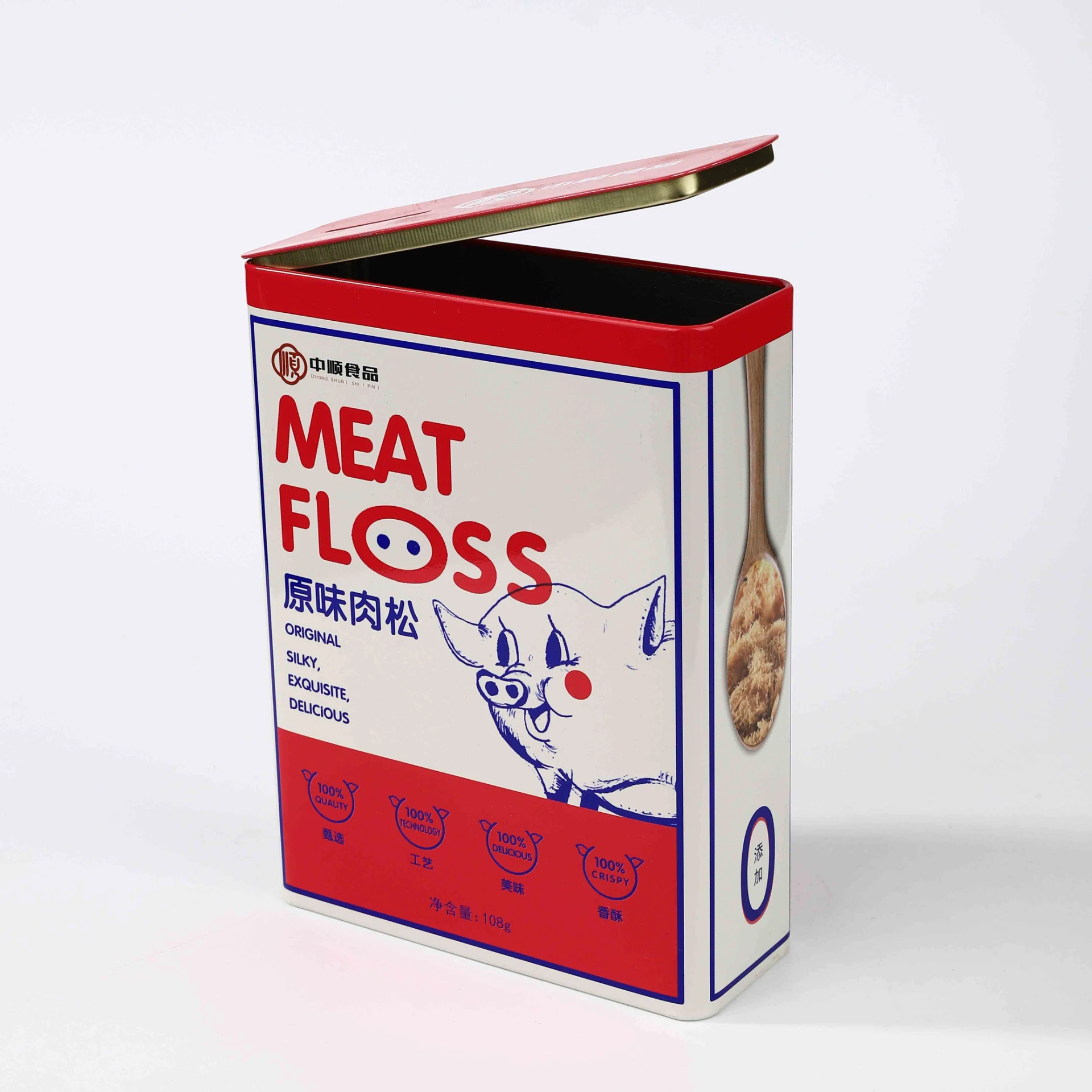

Metal tins, commonly made from steel or aluminum, are favored for their durability, recyclability, and ability to maintain product integrity. They are widely used for packaging food items, beverages, cosmetics, and even industrial components. The resistance of metal tins to moisture and contamination makes them a preferred choice for preserving the freshness and safety of products.

Large suppliers of metal tins typically offer a variety of products, including standard containers, custom shapes, and specialized designs tailored to specific industries. This versatility is essential for manufacturers that require unique packaging solutions to differentiate their products in a competitive marketplace.

The Supply Chain Dynamics

The journey of a metal tin begins with raw materials. Large metal tin suppliers often have established relationships with miners and refineries, allowing them to secure high-quality materials at competitive prices. This is a crucial element, as the cost of raw materials can significantly impact the final price of manufactured goods.

Once the raw materials are acquired, suppliers employ advanced manufacturing techniques to produce metal tins. These techniques may include stamping, welding, and coating, which increase efficiency and reduce waste. Furthermore, many suppliers are adopting sustainable practices, such as minimizing energy consumption and using recycled materials, in response to growing public and governmental demand for environmentally friendly operations.

Large metal tin suppliers not only focus on production but also on logistics. With the increase in globalization, the ability to deliver products on time is paramount. These suppliers often maintain extensive networks that help streamline the distribution process, ensuring that manufacturers receive their orders promptly and can keep their production schedules intact.

large metal tin supplier

Customization and Innovation

As consumer preferences shift and industries evolve, the need for customization has become increasingly important. Large metal tin suppliers are adapting by investing in innovative technologies that allow for personalization in design and branding. Digital printing, for instance, enables companies to create eye-catching graphics on metal tins, enhancing product appeal and brand recognition.

Moreover, advancements in technology have led to the development of smart packaging solutions. Some metal tins now incorporate QR codes and NFC technology that allow consumers to access information about the product, enhancing their overall experience. This level of innovation is vital for brands looking to engage consumers in a more meaningful way.

Challenges Facing Suppliers

Despite the robust demand for metal tins, large suppliers face numerous challenges. Fluctuations in raw material prices, regulatory changes, and increased competition can impact operations. Moreover, the recent disruptions in global supply chains have highlighted the vulnerabilities that many suppliers face.

In addition, environmental concerns are prompting regulatory bodies to impose stricter guidelines on manufacturing processes. Suppliers must ensure their operations remain compliant, which may require investments in new technologies and processes, thereby increasing operational costs.

Conclusion

In conclusion, large metal tin suppliers are vital players in the manufacturing sector, providing essential materials that support a wide range of industries. Their ability to adapt to changing market demands, invest in technology, and implement sustainable practices will determine their success in the evolving landscape of manufacturing. As consumer expectations continue to rise, these suppliers must be proactive in addressing challenges and embracing innovations to remain competitive. Ultimately, the partnership between manufacturers and metal tin suppliers will shape the future of packaging and product preservation across various industries, ensuring that they can meet the demands of a dynamic global market.

-

Custom Large Metal Box Manufacturers & Suppliers | Durable Solutions

NewsAug.22,2025

-

Top Steel Pail with Lid Manufacturers - Durable & Secure

NewsAug.19,2025

-

Large Metal Box Manufacturers: Custom & Durable Solutions

NewsAug.18,2025

-

Durable Large Metal Box Manufacturers & Custom Solutions

NewsAug.17,2025

-

Large Metal Box Manufacturers | Durable & Custom Solutions

NewsAug.16,2025

-

Top Steel Pail with Lid Manufacturers | Durable & Secure Solutions

NewsAug.15,2025