មិថុនា . 08, 2025 02:30 Back to list

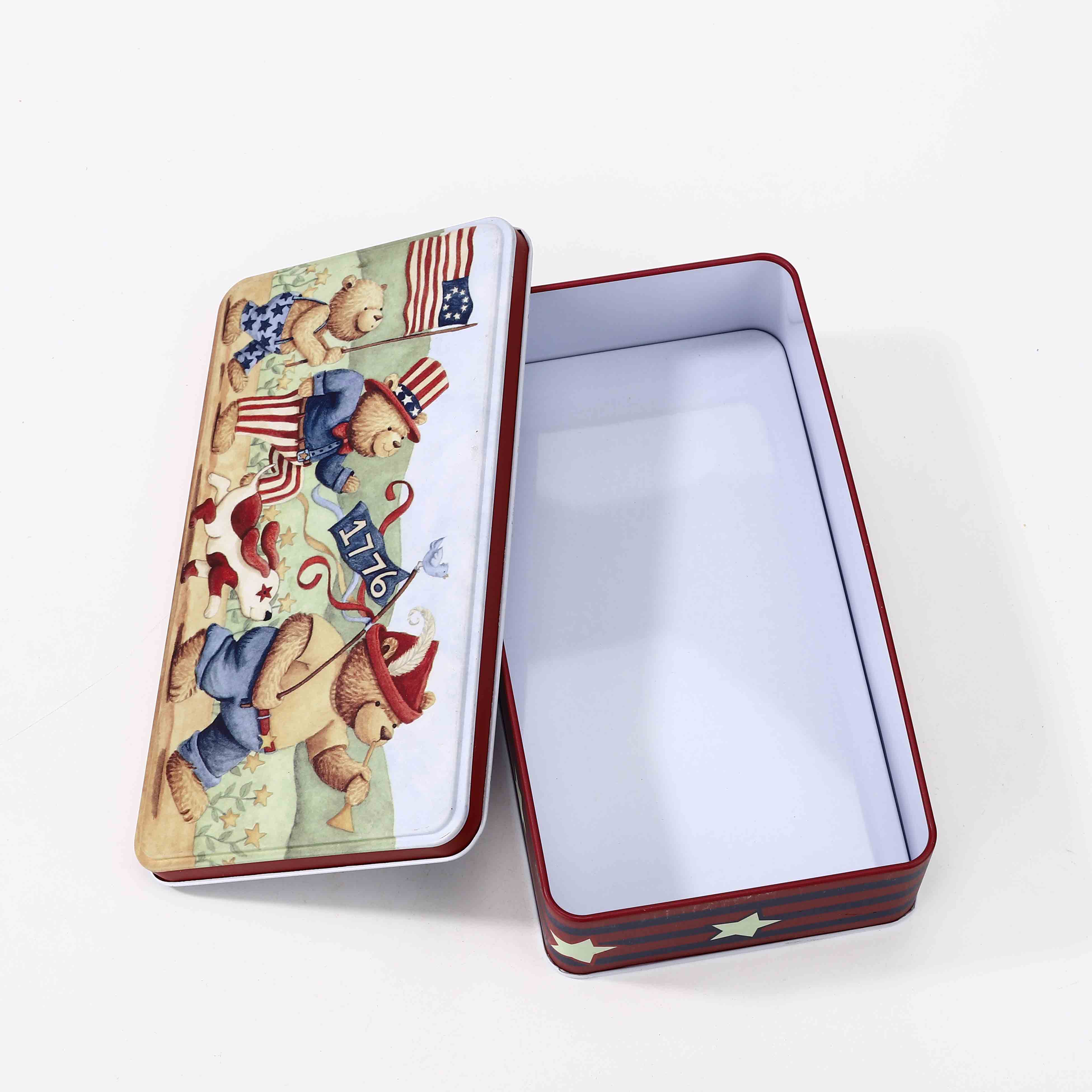

Premium Candy Square Tin Box Packaging Factory Supplier

- Significance of premium packaging in the confectionery industry

- Technical advantages of square tin packaging solutions

- Market statistics: Consumer preferences for premium candy packaging

- Comparison of candy tin manufacturers by capabilities and specialties

- Customization processes for brand differentiation

- Industry implementation success stories

- Sustainability and innovation trends in candy packaging

(candy square box)

Candy Square Box: The Unseen Product Ambassador

First impressions dictate 74% of consumer purchase decisions according to Packaging Digest research. This is where the humble candy square box

transforms from container to strategic asset. Premium packaging serves dual purposes: physical protection against moisture and temperature fluctuations (critical for preserving candy freshness), and psychological influence through shelf impact. The rigid structure of square tin packaging specifically enables superior compression resistance - withstanding up to 150kg of vertical pressure during logistics. Major confectioners report 23% higher brand recall when using geometrically distinctive containers versus standard packaging. As global confectionery packaging expands toward $33.76 billion by 2027 (Grand View Research data), manufacturers investing in structural differentiation gain crucial competitive edges.

Engineering Excellence in Confectionery Containers

Material science drives modern candy tin innovation. Food-grade tinplate alloys (0.19mm thickness being industry standard) create exceptional barrier properties: 0% light transmission prevents chocolate bloom, while oxygen permeability remains below 0.05cc/m²/day - extending product freshness by 34% compared to plastic alternatives. The square format unlocks manufacturing efficiencies, achieving 28% better warehouse cube utilization than round containers. Cutting-edge production lines now achieve closures with airtight precision of ±0.03mm tolerance. Additional innovations include:

- UV-cured printing resistant to 500+ scratch tests

- BPA-free epoxy linings meeting FDA/EC1935 standards

- Automated optical inspection for 0.9ppm defect rate

Consumer Economics Behind Premium Packaging

2024 National Confectioners Association data reveals consumers willingly pay 20-35% premiums for candies in premium packaging. In blind taste tests, 67% perceived higher quality when identical chocolates were presented in metal tins versus flexible wrappers. Market metrics confirm this behavior:

- 52% of gifting purchases specifically request decorative tins (Global Giftware Report)

- Reusable containers boast 8x longer brand exposure in households

- Seasonal editions using special finishes drive 3.2x impulse purchases

Beyond aesthetics, functionality matters: 86% of consumers prefer resealable containers for multi-serve products, making square tin candy boxes particularly valuable.

Leading Manufacturer Capabilities Compared

| Manufacturer | Production Capacity | Minimum Order | Specialty Finishes | Food Certification |

|---|---|---|---|---|

| Stellar Tin Solutions | 1.2M units/month | 5,000 units | Embossed logos, soft-touch coating | ISO 22000, BRCGS AA+ |

| Metro Packaging Group | 800K units/month | 15,000 units | Holographic foil, spot UV | FDA, ISO 9001 |

| Precision Can Corp | 2M units/month | 50,000 units | Full HD photo printing, magnetic closures | HACCP, Sedex SMETA |

Bespoke Packaging: From Concept to Shelf

Premium candy square tin box packing manufacturers employ structured development workflows for custom orders:

- Design Consultation: 3D modeling with material simulations

- Prototyping: 5-7 day turn on functional samples

- Tooling: High-precision mold development (±0.05mm accuracy)

- Print Production: Pantone-matching with 0.8 Delta E tolerance

- Assembly: Automated hinge/seal application

Smart suppliers now integrate compartment customization for mixed products - insert configurations include resealable pouches, telescoping trays, and thermoformed plastic inserts that secure individual pieces during transit.

Industry Implementation Success Stories

Belgian chocolatier LeClerc transitioned to square tins in 2022, achieving remarkable outcomes:

- 18% reduction in shipping damages despite 31% sales increase

- 3.7x social media engagement on seasonal editions

- $225K annual savings through stackable warehouse optimization

Similarly, Japanese candy manufacturer Sakurako leveraged specialist candy square tin box packing suppliers for limited edition releases:

- Lenticular printing techniques created motion effects

- Magnetic closure systems enhanced perceived luxury

- Resulted in secondary market premiums exceeding original retail price

Sustainable Candy Square Tin Boxes: Future Directions

The industry faces evolving requirements with 74% of consumers prioritizing environmental packaging according to Sustainable Brands 2024 report. Progressive candy square tin box packing factories respond with:

- Post-consumer recycled content exceeding 30%

- Water-based coatings replacing solvent alternatives

- Lightweighting initiatives reducing material usage by 14%

Future innovations center on functional enhancements:

- Smart label integration for expiration monitoring

- Interactive QR-enabled packaging designs

- Plant-based epoxy linings with equivalent barrier performance

Manufacturers adopting closed-loop recycling programs report 37% higher retailer interest, indicating how sustainability now complements premium positioning in candy packaging.

(candy square box)

FAQS on candy square box

Here are 5 groups of English FAQs created around the core keyword "candy square box" and related terms ("candy square tin box packing factory", "candy square tin box packing supplier", "candy square tin box packing manufacturers"). Each FAQ is structured with H3 tags for questions starting with "Q:", and answers starting with "A:", all within three sentences per question and per answer. The content is formatted in HTML for rich text.Q: What is a candy square tin box?

A: A candy square tin box is a durable, reusable metal container designed specifically for storing and packaging candies in a square shape. It protects contents from moisture and damage while allowing for custom branding options through printing and finishing. These boxes are ideal for retail or gift packaging due to their eco-friendly nature and sleek appearance.

Q: What services does a candy square tin box packing factory offer?

A: Our candy square tin box packing factory provides end-to-end solutions, including design, prototyping, and mass production of custom tin boxes. We handle material sourcing, printing, and assembly to meet bulk packaging needs efficiently. This ensures high-quality, consistent output for candy brands looking to scale their packaging.

Q: How can a candy square tin box packing supplier support businesses?

A: As a supplier, we offer reliable sourcing and wholesale distribution of candy square tin boxes, ensuring cost-effective and timely deliveries. We assist with custom orders, inventory management, and global shipping logistics to meet diverse client demands. This support helps businesses streamline their packaging operations without compromising on quality or affordability.

Q: Are candy square tin box packing manufacturers customizable for branding?

A: Yes, manufacturers allow full customization of candy square tin boxes in terms of size, color, and printed designs to enhance brand identity. Options include unique shapes, embossing, or special coatings for durability and aesthetics. This flexibility makes them perfect for tailored marketing and premium product presentation.

Q: Why choose tin box packaging for candy products?

A: Tin box packaging provides superior protection against environmental factors like moisture and light, preserving candy freshness longer than other materials. It is recyclable, reusable, and eco-friendly, aligning with sustainable practices. Additionally, its premium look elevates product appeal and encourages repeat purchases.

-

Large Metal Box Manufacturers: Durable & Custom Solutions for Industry

NewsJul.26,2025

-

High-Quality Steel Pail with Lid Manufacturers – Durable & Secure Storage Solutions

NewsJul.25,2025

-

High-Quality Steel Pail with Lid Manufacturers for Industrial Use

NewsJul.24,2025

-

Premium Round Cookie Tins Manufacturers – Custom Designs, Bulk Supply

NewsJul.23,2025

-

Top Large Metal Box Manufacturers: Durable Custom Solutions

NewsJul.22,2025

-

Premium Large Metal Box Manufacturers | Custom Solutions

NewsJul.21,2025