-

The Evolution Of Tin Cans For Food Packaging food tin

Tin cans for food packaging have come a long way. From small jars used for preserving food to metal cans that can store food for longer, the history of food packaging has come a long way today.Legu pli -

The Elemental Difference Between Aluminum And Tin For Canned Foods food tin

Take a moment to envision the periodic table ... yep, that massive diagram that may have given you nightmares in high school and college. Remember atomic numbers 13 and 50, aluminum and tin?Legu pli -

Everything You Need to Know About the Food Safety of Canned Foods food tin

Canning is an important and safe method for preserving food. Manufactured canned foods like sauces, beans, lentils, pastas, tuna, vegetables and fruits are pantry staples.Legu pli -

Why Are Some Foods Canned In Tin And Others In Aluminum? food tin

Many of our everyday meals and beverages, as well as products, are canned. This has been the case for much longer than you may believe. The canning technology around foods, pet food, paint, oil, and chemicals has developed over time to include screw tops, ring pulls, stay-on tabs, and recyclable double-seamed seams.Legu pli -

PRODUCTION STANDARD REQUIREMENTS FOR FOOD TIN CANS! food tin

Food tin cans are food packaging boxes made of tinned thin steel plates through different processes such as welding, stamping or buckling, which can be used to package and protect food.Legu pli -

Learn why tin cans become more important in food packaging food tin

As we all know, the food industry has stricter requirements for packaging, not only in quality, but also in safety. Nowadays, many food packages in the market use metal cans. Metal tin cans are widely used in the food packaging industry.Legu pli -

Types of Packaging Cans food tin

Packaging is a broad category in the manufacturing industry. Different products necessitate different packaging options in order to be packaged securely and according to industry standards. Packaging cans have been so popular recently am sure you have used one at some point. Numerous advantages they offer users are the main reason for their popularity in different industries.Legu pli -

The Difference Between Tin Cans and Aluminum Cans food tin

The word 'Tin Can' in today's world is used to sum up all sorts of small metal tins into one category. Most of these modern tin containers are crafted out of aluminum, however, originally this was not the case. Although it is common for people to refer to tin cans and aluminum cans as the same item, these two types of tins are actually quite different from one another.Legu pli -

The Science Behind Why Some Foods Are Canned In Tin Vs. Aluminum food tin

Here's a little experiment to try in your pantry. Grab the first canned food you see and test it with a magnet. If the magnet sticks, it means the can you grabbed is made of tin, and if the magnet fails, it means the can is made of aluminum.Legu pli -

How tinplate cans are made today?

The tin coating is applied by continuous electro-deposition of tin on to thin steel strip, after which the tinplate is either sold in coil form or cut into sheets for the can manufacturer.At the can manufacturers, the tinplate is slit into rectangular “body blanks” which are then rolled into a cylindrical shape and the contacting edges welded together at very high speeds. The ends of this cylinder are flanged, ready to receive the can ends.Legu pli -

Tin can

A tin can, also called a tin (especially in British English) or a can, is an air-tight container that is made of metal and used for the distribution or storage of goods. Most "tin cans" are not made solely of tin but of tin-plated steel. Opening a can requires cutting or tearing of the metal.Legu pli -

The Manufacturing Process of Metal Cans

The manufacturing process of metal cans typically begins with the selection of suitable materials. Steel is the primary metals used due to their durability, strength, and recyclability. These metals undergo a series of transformations to become the sturdy cans we encounter in stores.The first step is metal preparation. The chosen metal is processed into sheets or coils, ensuring uniform thickness and quality. These sheets serve as the foundation for the subsequent stages of can production.Legu pli -

Tin can manufacturing process

Tin is a relatively sturdy material that can hold up to wear and tear quite well, so it’s hard to damage it. In addition, tin boxes are durable, making them an excellent choice for storing items you want to keep safe. Light, soft enough to be shaped, and sturdy, tin is a practical and useful material for storing a wide array of items. Though we use tin boxes a lot in our daily lives, we don’t often stop and think about how these handy items are made. We hope that this article has given you more information and a renewed appreciation for this often overlooked storage solution.Legu pli -

Types of Packaging Cans

Packaging is a broad category in the manufacturing industry. Different products necessitate different packaging options in order to be packaged securely and according to industry standards. Packaging cans have been so popular recently am sure you have used one at some point. Numerous advantages they offer users are the main reason for their popularity in different industries.Legu pli -

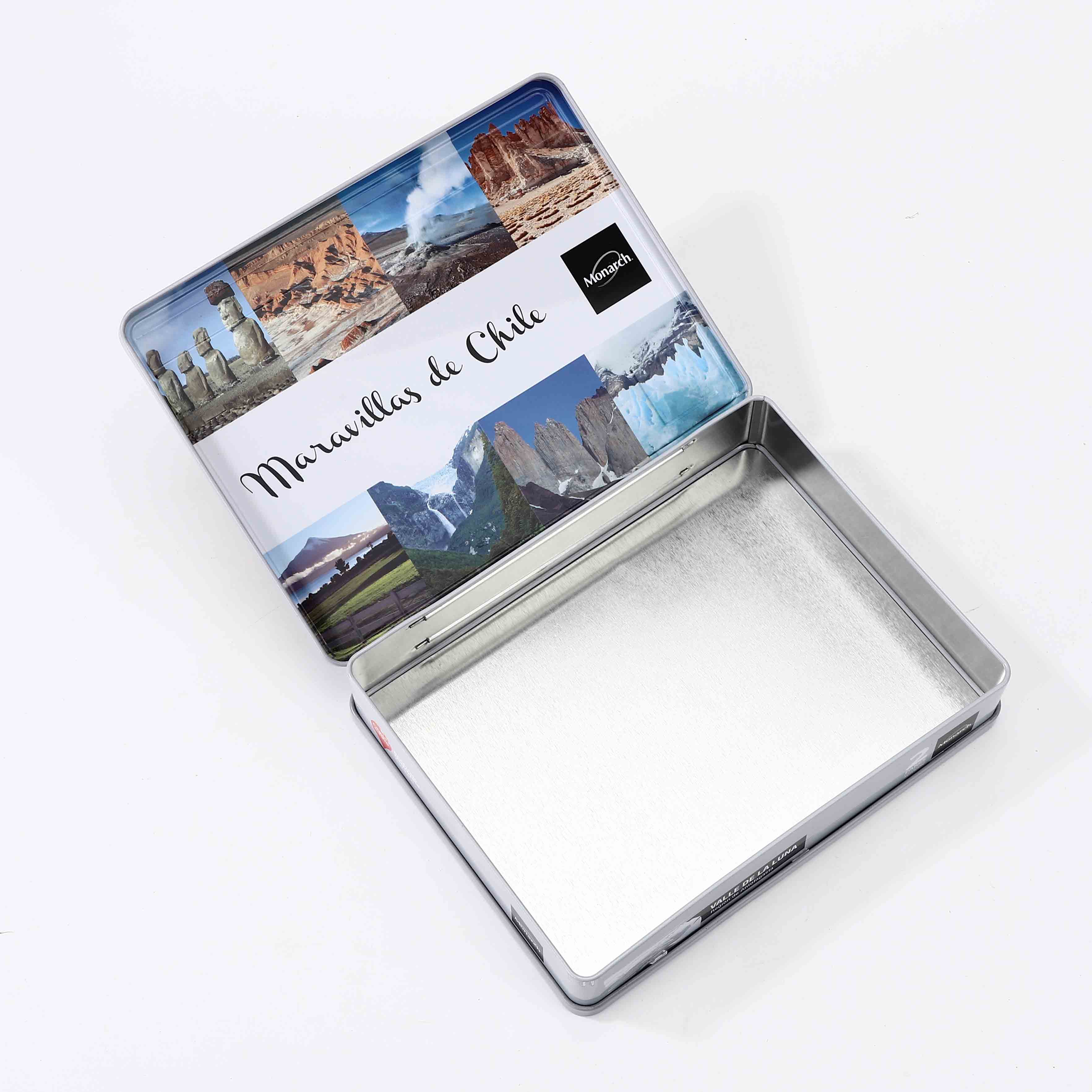

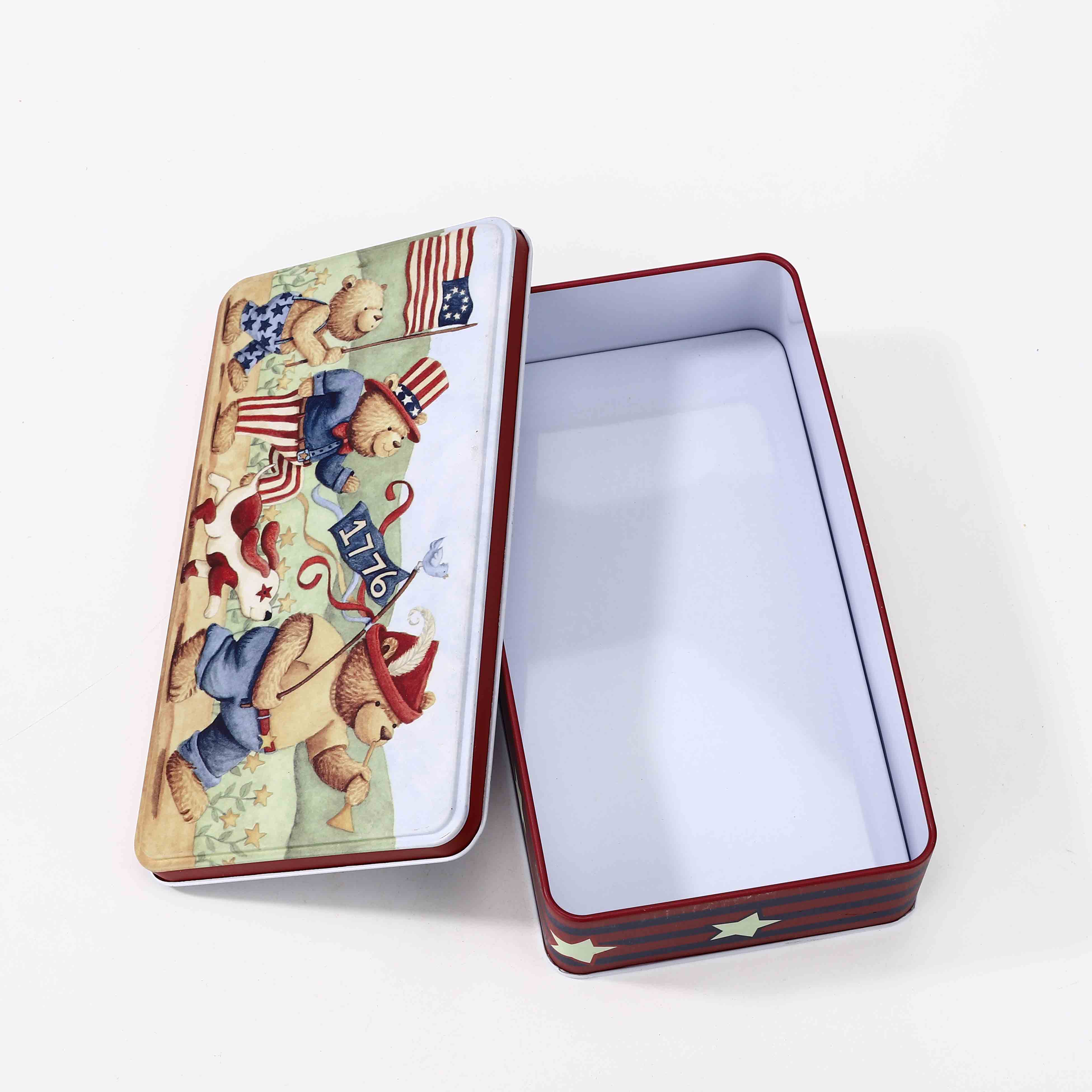

Why You Should Be Using Tin Packaging

Tin containers are a popular packaging choice in the cosmetic and food industries. They can be used to store and distribute cosmetics, food and candy, candles, medicine, and more. Typically made of thin iron or aluminum with a tin plating, these metal packages can be made in any size, shape, or color.Legu pli -

What Are Tin Cans Made Of?

Of course, tin is only the traditional way to make cans. Many cans today are made of aluminum or different types of treat metal, as long as that metal can be formed into the can shape and is resistant to corrosion and rust. Both older tin cans and newer versions are recyclable, which allows manufacturers to strip away the tin and other valuable parts of the can and use the steel or iron for scrap metal.Legu pli